TOYOTA KATA

CULTURA DE MEJORA CONTINUA

MEJORA TU CALIDAD Y COSTO CON: TOYOTA KATA

Inicia el proceso de implementación de Toyota Kata en tu Empresa y empieza a conocer el siguiente nivel de Mejora Continua de Calidad, Costo y Entrega mientras desarrollas Líderes Lean y Factor Humano.

VISUALIZA EL CICLO DE COACHING AQUÍ:

EGRESADO DEL CURSO TOYOTA KATA

- Coach capaz de Iniciar el proceso de implementación del Toyota Kata en tu empresa.

- Mejorará sus habilidades para lograr fuertes resultados en Calidad, Servicio, Costo, Capacidad y Entrega.

- Manejara el Coaching aplicado a la industria en la cual se desempeña y aplicarla en distintos giros.

PLANTA HOST:

Planta Motores

Planta Motores

Superficie: 111,483 metros cuadrados.

Productos: Produce motores 5.7L V-8 HEMI para los vehículos Chrysler 300, Dodge Charger, Dodge Challenger, RAM 1500 y 2500, Jeep Grand Cherokee SRT, el motor 6.4L V-8 para los vehículos Chrysler 300, Dodge Challenger, Dodge Charger, Ram Heavy Duty 3500y Jeep Grand Cherokee, el motor 6.2L V-8 HEMI® Hellcat alimentado por un supercargador, capaz de desarrollar 707 caballos de fuerza, siendo el V8 de producción más poderoso y el motor Tigershark 2.4L para el Dodge Dart, Chrysler 200, Jep Compass, Jeep Patriot y Jeep® Cherokee.

Personal: 1,459.

Sindicato: SINDICATO NACIONAL DE TRABAJADORES DE LA INDUSTRIA AUTOMOTRIZ INTEGRADA, SIMILARES Y CONEXOS DE LA REPUBLICA MEXICANA (CTM).

Historia de la Planta: Fue inaugurada el 8 de mayo de 1981 por el ex presidente José López Portillo. El motor 5.7L HEMI fue lanzado en junio de 2002. En octubre del 2013 se hizo el anuncio de inversión de $164 MDD para agregar una línea de producción para ensamblar los motores Tigershark 2.0L y 2.4L.

VISITA A LA PLANTA:

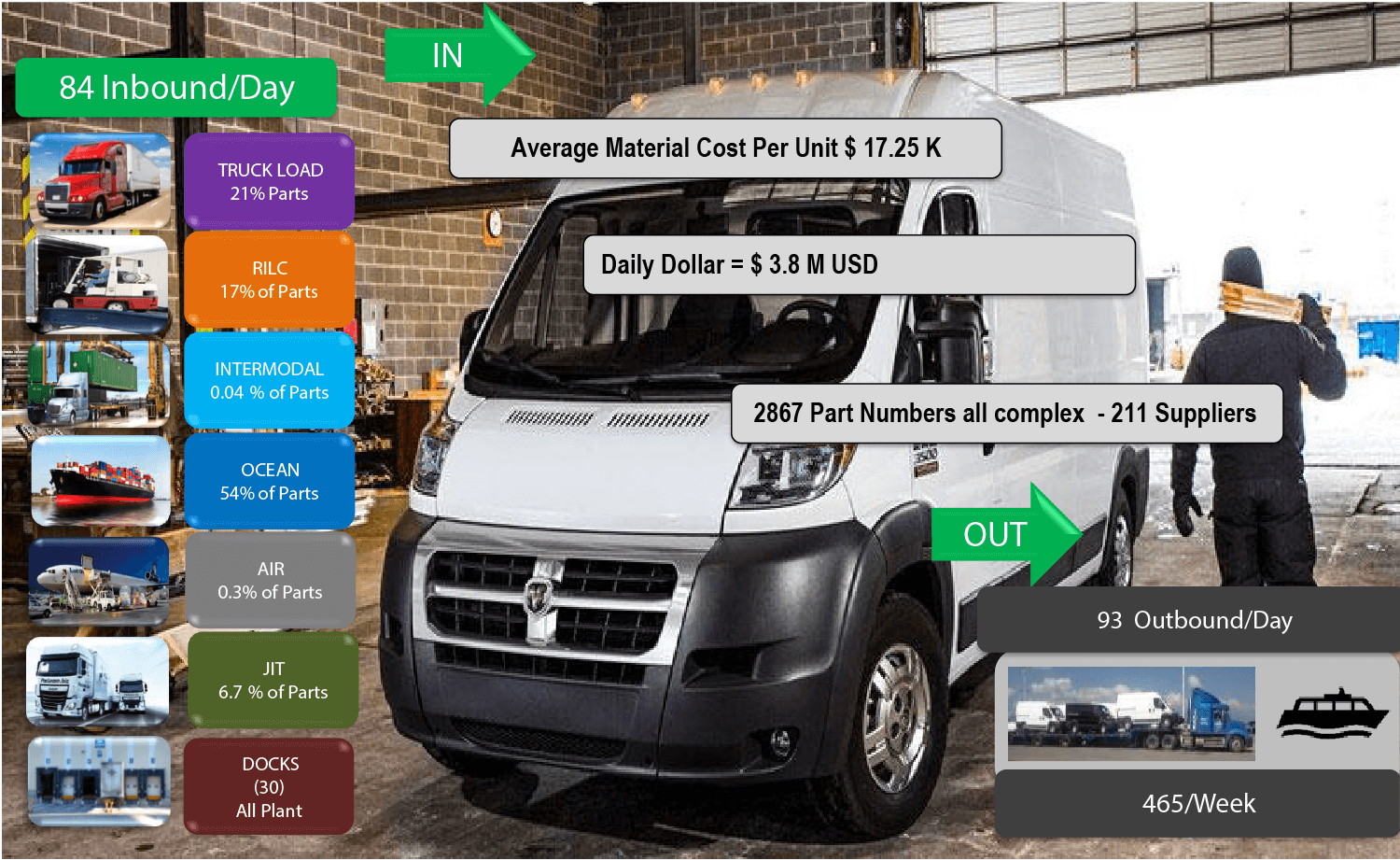

Planta Ensamble Van

Planta Ensamble Van

Superficie: 262,100 metros cuadrados.

Productos: Produce el nuevo vehículo comercial Ram ProMaster.

Personal: 1,610.

Sindicato: SINDICATO NACIONAL DE TRABAJADORES DE LA INDUSTRIA AUTOMOTRIZ INTEGRADA, SIMILARES Y CONEXOS DE LA REPUBLICA MEXICANA (CTM).

Historia de la Planta: Fue inaugurada el 10 de octubre de 2013 por el Presidente de la República Mexicana Enrique Peña Nieto y Sergio Marchionne, Presidente y CEO de Grupo Chrysler LLC , para la construcción de esta planta se hizo una inversión de $1,085 MDD.

TRADUCIDO A 17 IDIOMAS

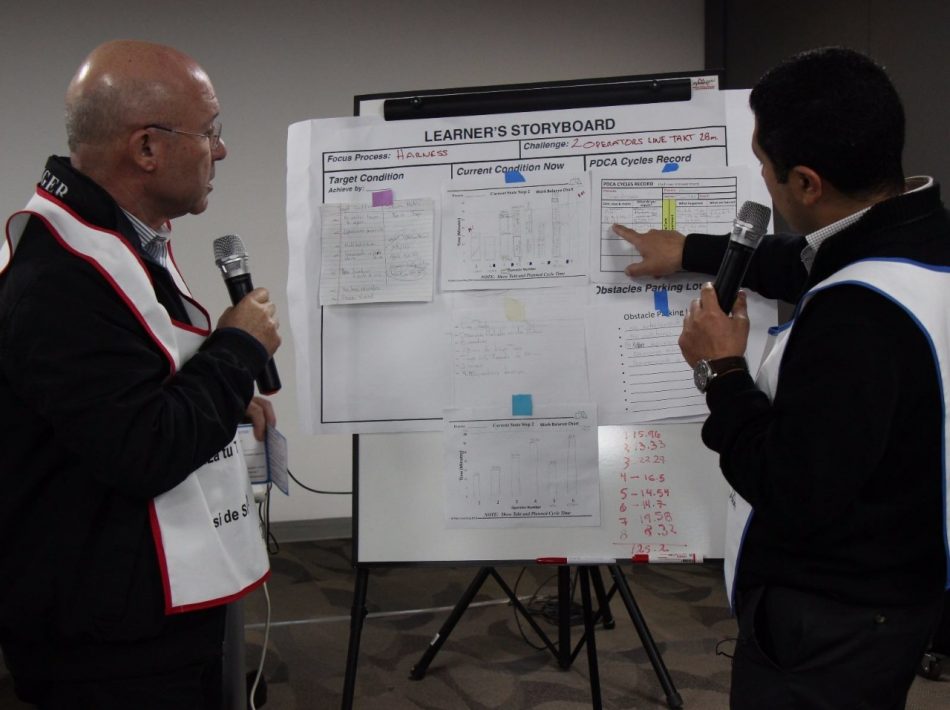

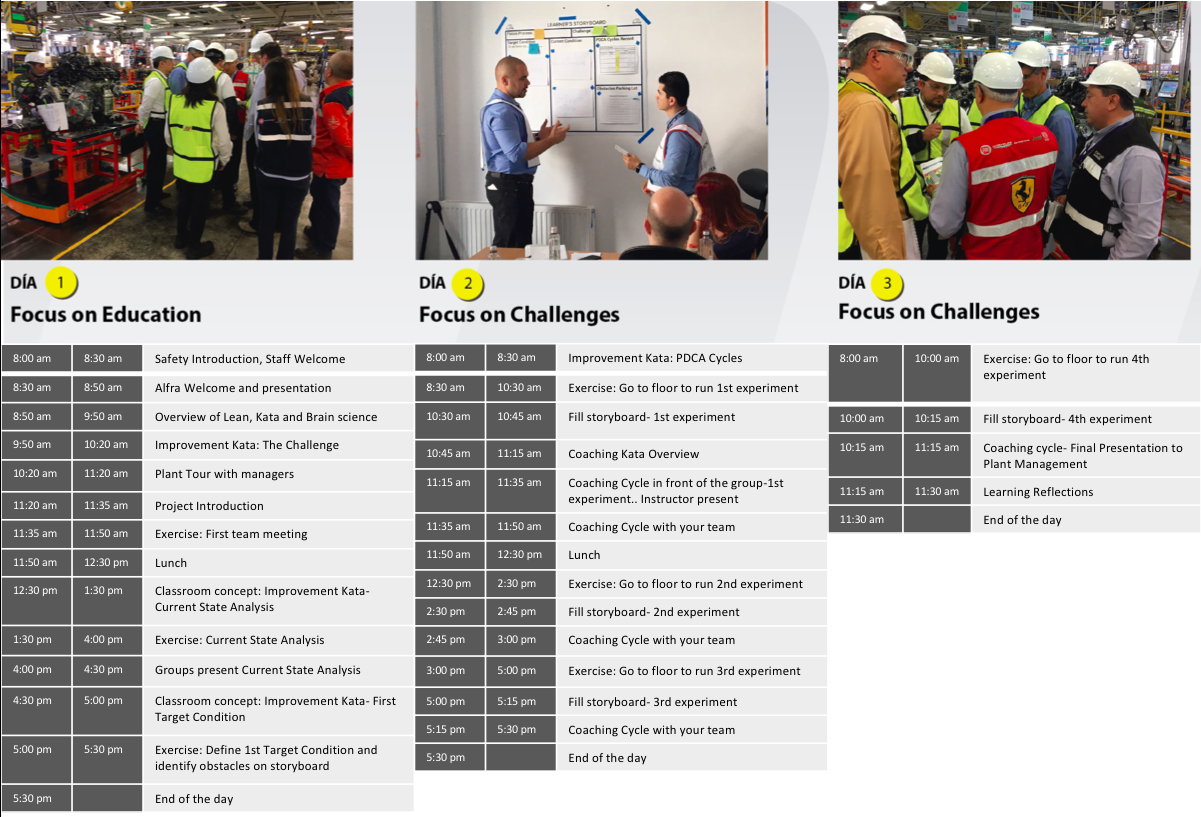

PROGRAMA

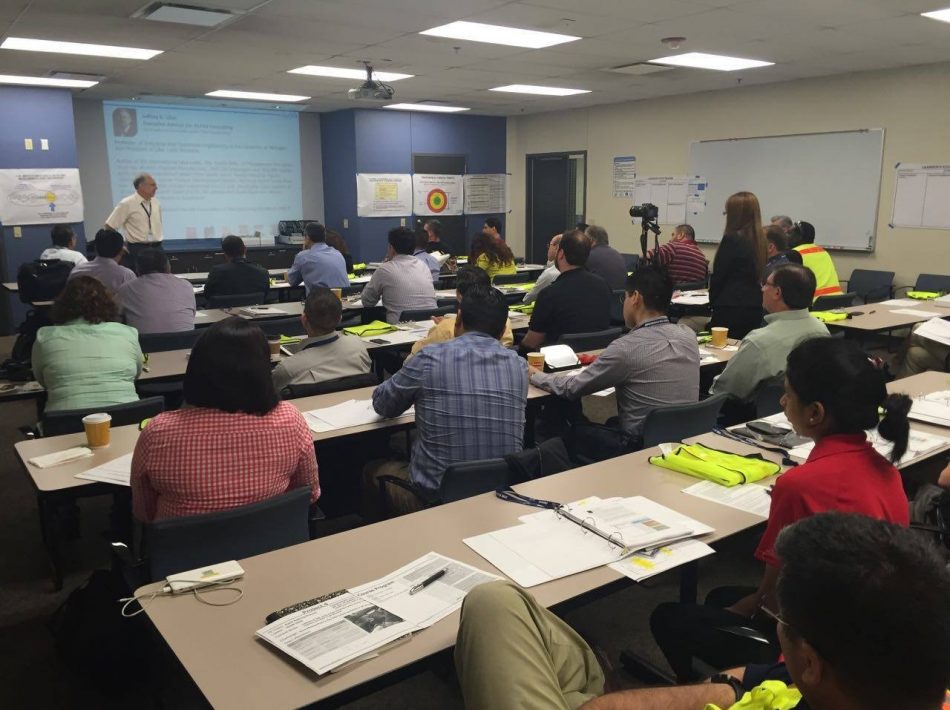

EXPOSITORES

LIDIA FLORES

Has trained and coached more than 100 clients on Lean Office, Lean Manufacturing, and Toyota Kata Instructor including General Managers. Participated on the DeAcero Production System development. Lean Office in field training and implementation to potentially reduce lead time from 16 to 10 days on San Mina.

Lidia has experience on the Toyota Way, Toyota Kata, Lean Leadership, Gemba Training for the last 5 years, she had been trained by Francisco Ocejo, Alfra Consulting Director Manager; Jeffrey Liker, author of the international best-seller The Toyota Way: 14 Management Principles; Ritshuo Shingo, who is Shigeo Shingo son and was the first president of JV Toyota China in 1998; Top Former Toyota Management. Lida Expertise is Lean Transformations under ALFRA Methodology: Hoshin Kanri, Daily KPI Management, Lean Operations, Lean Supply Chain, TPM, Problem Solving and Toyota Kata.

Lidia has trained more than 100 clients on Lean Manufacturing, including General Managers, Manufacturing engineer, Quality, Finance and Logistics. She also is Lean Office Instructor with experience on Logistics, Service company, Human Resources, Purchasing and Engineering change projects improvement.

Lidia´s principal customers and trainings:

–Berry Global: Lean Transformation implementing Top Management to the each level closest to the Gemba in Quality, Opertions, Maintenance, Supply.

— Bitrón Automotive: Lean Transformation implementing Top Management to the each level closest to the Gemba in Quality, Opertions, Maintenance, Supply.

– Daimler Mercedes Benz, a bus assembly division; Lean Office and Toyota Kata training where we improve the engineering change applying Lean Office.

– San Mina, an Oil and Gas Company, Lean Office training and consulting, we reduce the total lead time from 10 to 5 days on the logistic chain including planning, purchasing, materials and engineering.

– DeAcero, wire division and steel. She participate on the DeAcero Production System, developing a continuous improvement system for logistic, purchasing, planning, shipping and production.

She has taught classes on Lean Manufacturing, Lean Logistics, Toyota Kata and Lean Office for different Universities as Tecnológico de Monterrey, UANL, UDEM, Universidad de Poza Rica, Universidad de Anáhuac, UPAEP.

Customers supported: