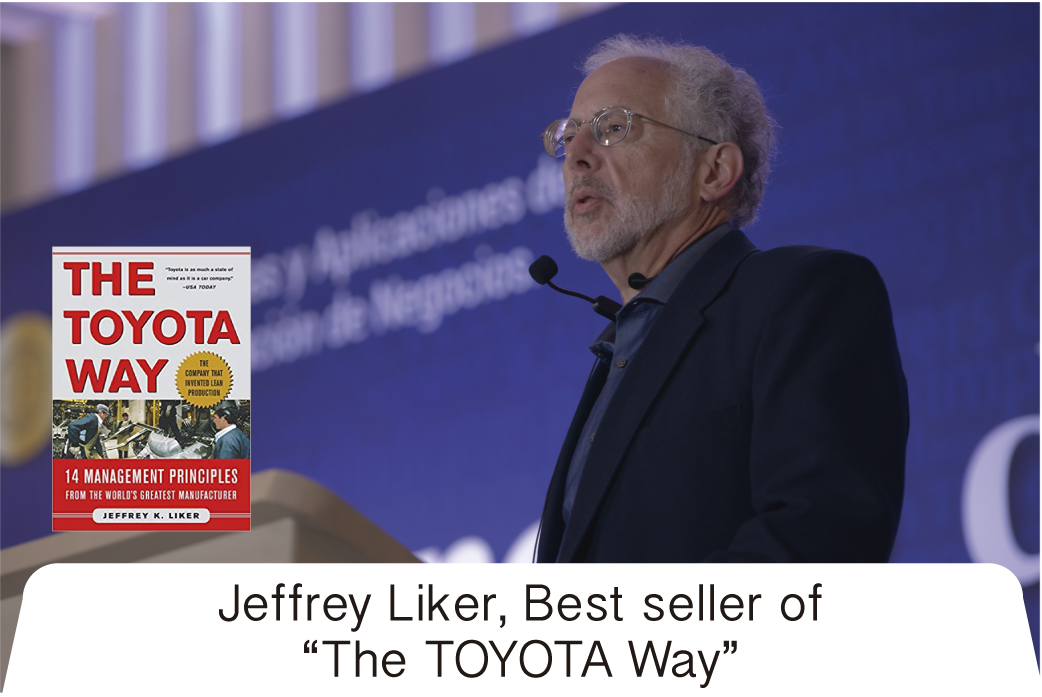

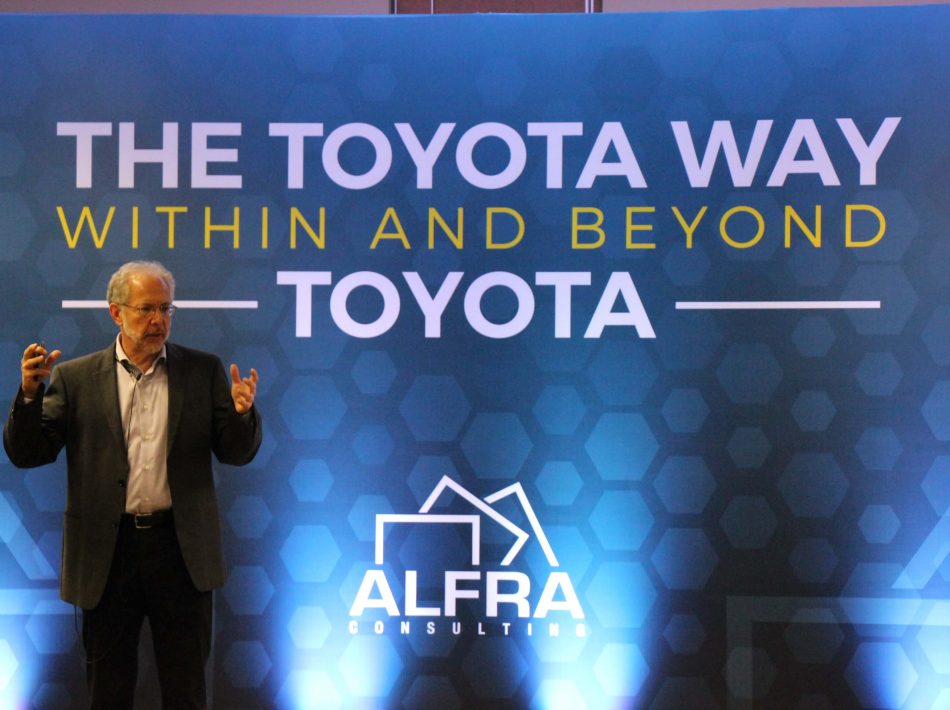

TOYOTA WAY 2ND EDITION

The bestselling guide to Toyota’s legendary philosophy and production system–updated with important new frameworks for driving innovation and quality in your business

One of the most impactful business guides published in the 21st Century, The Toyota Way played an outsized role in launching the continuous-improvement movement that continues unabated today.

Multiple Shingo Award-winning management and operations expert Jeffrey K. Liker provides a deep dive into Toyota’s world-changing processes, showing how you can learn from it to develop your own improvement program that fits your conditions. Thanks in large part to this book, managers across the globe are creating workforces and systems that produce the highest-quality products and services, establish and retain customer loyalty, and drive business profitability and sustainability. Now, Liker has thoroughly updated his classic guide to include:

Completely revised data and updated information about Toyota’s approach to competitiveness in the new world of mobility and smart technology

Illustrative examples from manufacturing and service organizations that have learned and improved from the Toyota Way

A fresh approach to leadership models

The brain science and skills for learning to think scientifically

How Toyota applies Hoshin Kanri, a planning process that aligns objectives at all levels and marries them to business strategy

Organized into thematic sections covering the various aspects of the Toyota Way–including Philosophy, Processes, People, and Problem Solving–this unparalleled guide details the 14 key principles for building the foundation of a powerful improvement system and managing it for ultimate competitive advantage.

With The Toyota Way, you have an inspiration and a model of how to set a direction, continuously improve and learn at all levels, continually flow value to satisfy customers, improve your leadership, and get quality right the first time.

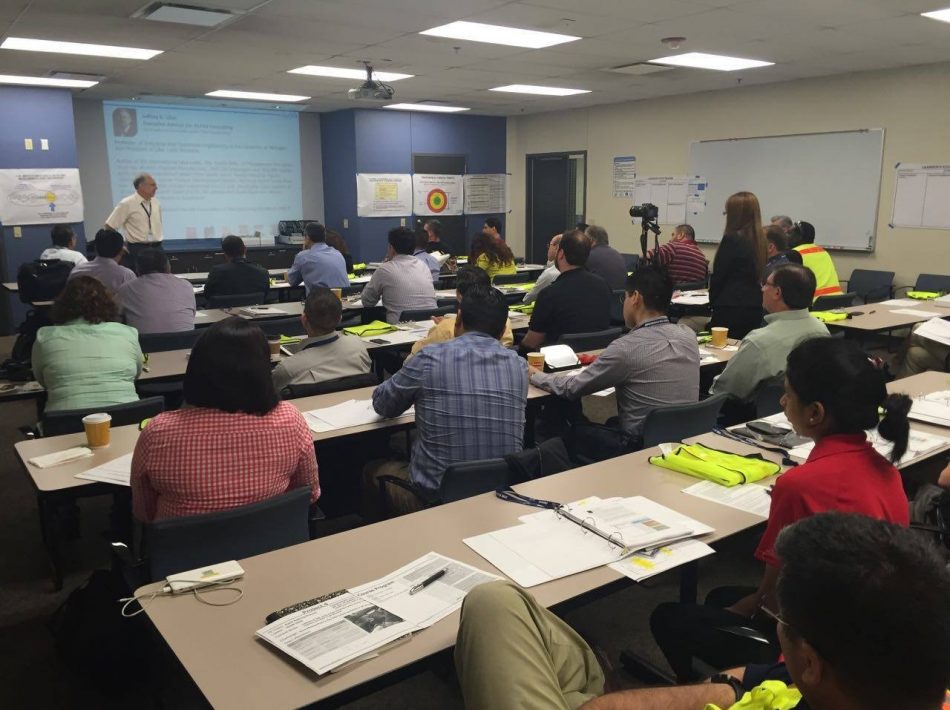

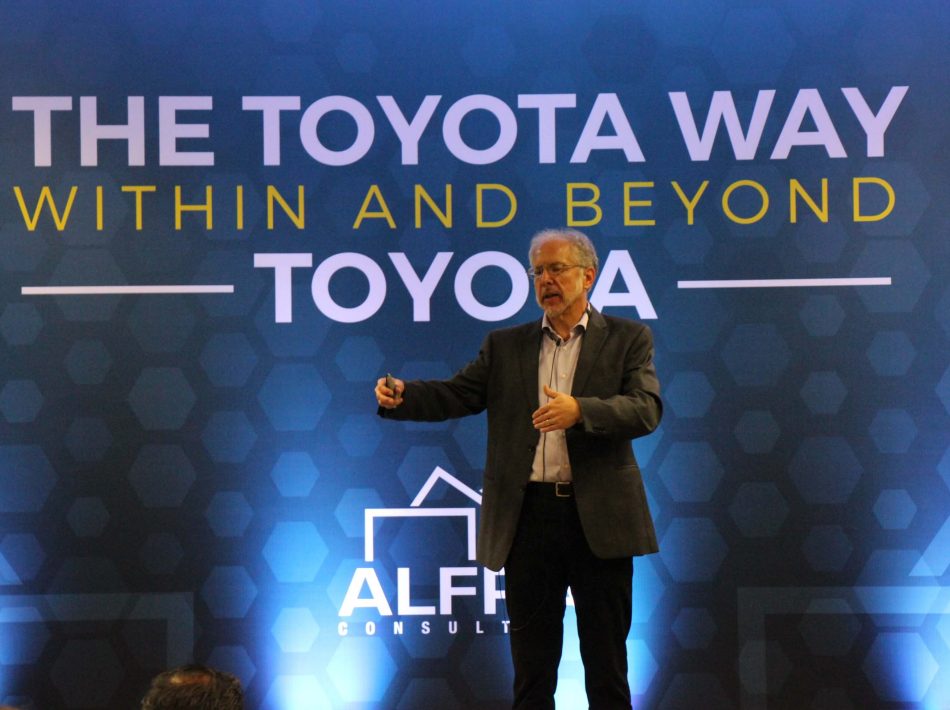

PROGRAM

1.The Toyota Way model and philosophy

- The Toyota Way evolved from founders to today (history)

- The Toyota Way 2001 House

- Liker’s Revised 4P model of the Toyota Way: Scientific thinking is at the center

- Principle 1: Long-term Systems Thinking

- Thinking of the organization as a machine versus and organizm

- Exercise—Each participant lists out characteristics of mechanistic lean deployment versus organic lean deployment

- Finding the balance between mechanistic and organic

2.Lean Processes (principles 2-8)

- Summarize process principles

- Keypoint 1: Lean processes make problems visible

- Keypoint 2: Lean processes are a dependent variable to strive toward not an independent variable to implement

- Continuous flow in software development: Menlo Innovations example

- Digitial technology and Lean

- Self assessment: Lean tools vs lean to support continuous improvement

3.Developing people to think scientifically (principles 9-12)

- Lean leadership development model

- Starter Kata to practice scientific thinking:

- exercise 1: signing name with dominant versus non-dominant hand)

- exercise 2: Learning to spin a pencil

- The role of the work group

- span of coaching of 4:1

- Continuous improvement in the work group

- The Human resource system to support work groups

- Self assessment: structure for developing and supporting work groups

4. Aligning strategy to execution (principles 13 and 14)

- Hoshin Kanri

- Hoshin Kanri as mechanistic tool vs organic process of developing people and achieving goals

- The role of strategy in lean

- Contrasting Toyota strategy vs Tesla strategy

-

Self assessment: structure for developing and supporting work groups

5.Leading Lean Transformation

- Mechanistic vs organic approach to transformation

- Role of the model line

- Defeating entropy

- Balancing spreading wide versus deep

- Overall assessment of current condition on the fourteen principles

- Vision for where we want to be in the next year on the principles