Improve your Quality and Cost with: Toyota Kata

DATE & HOST

November 10th to 12th 2020

San Luis Potosí

San Luis Potosí

Why SILGAN?

Because you will take the borrowed learning curve and earn at least 1 year in the speed of your own implementation.

SILGAN’s team from its plant management, David Ayala, have strong management systems at all levels (Hoshin Kanri & EMDS) to connect with their Improvement Katas.

Start the process of implementing Toyota Kata in your Company and start to know the next level of Continuous Improvement of Quality, Cost and Delivery while developing Lean Leaders and Human Factor.

DISPLAY THE COACHING CYCLE HERE:

GRADUATE OF THE TOYOTA KATA COURSE

- Coach able to start the process of implementing the Toyota Kata in your company.

- Improve your skills to achieve strong results in Quality, Service, Cost, Capacity and Delivery.

- Manage the Coaching applied to the industry in which it operates and apply it in different ways.

HOST PLANT:

FCA Chrysler

FCA Chrysler

Surface: 111,483 square meters.

Products: Produces 5.7L V-8 HEMI engines for Chrysler 300, Dodge Charger, Dodge Challenger, RAM 1500 and 2500 vehicles, Jeep Grand Cherokee SRT, 6.4L V-8 engine for Chrysler 300 vehicles, Dodge Challenger, Dodge Charger , Ram Heavy Duty 3500 and Jeep Grand Cherokee, the 6.2L V-8 engine HEMI® Hellcat powered by a supercharger, capable of developing 707 horsepower, being the most powerful production V8 and the Tigershark 2.4L engine for the Dodge Dart, Chrysler 200, Jep Compass, Jeep Patriot and Jeep® Cherokee.

Personnel: 1,459.

Syndicate: NATIONAL UNION OF WORKERS OF THE INTEGRATED AUTOMOTIVE INDUSTRY, SIMILAR AND RELATED OF THE MEXICAN REPUBLIC (CTM).

History of the Plant: It was inaugurated on May 8, 1981 by former President José López Portillo. The 5.7L HEMI engine was launched in June 2002. In October 2013 the investment announcement of $ 164 million was made to add a production line to assemble the Tigershark 2.0L and 2.4L engines.

PLANT VISIT:

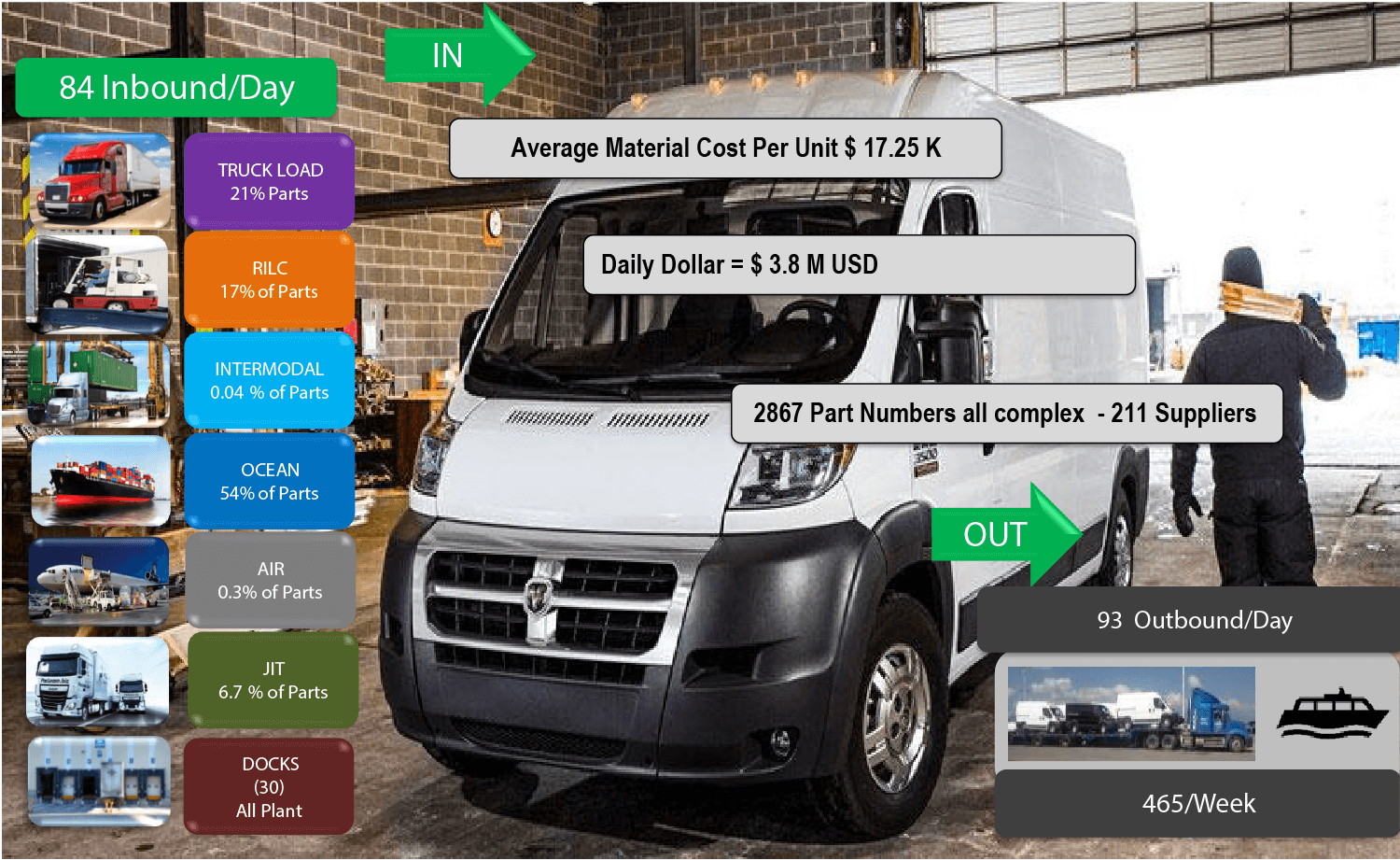

Plant Assembly Van

Plant Assembly Van

Surface: 262,100 square meters.

Products: Produces the new Ram ProMaster commercial vehicle.

Staff: 1,610

Syndicate: NATIONAL UNION OF WORKERS OF THE INTEGRATED AUTOMOTIVE INDUSTRY, SIMILAR AND RELATED OF THE MEXICAN REPUBLIC (CTM).

History of the Plant: It was inaugurated on October 10, 2013 by the President of the Mexican Republic Enrique Peña Nieto and Sergio Marchionne, President and CEO of Grupo Chrysler LLC, for the construction of this plant an investment of $ 1,085 MDD was made.

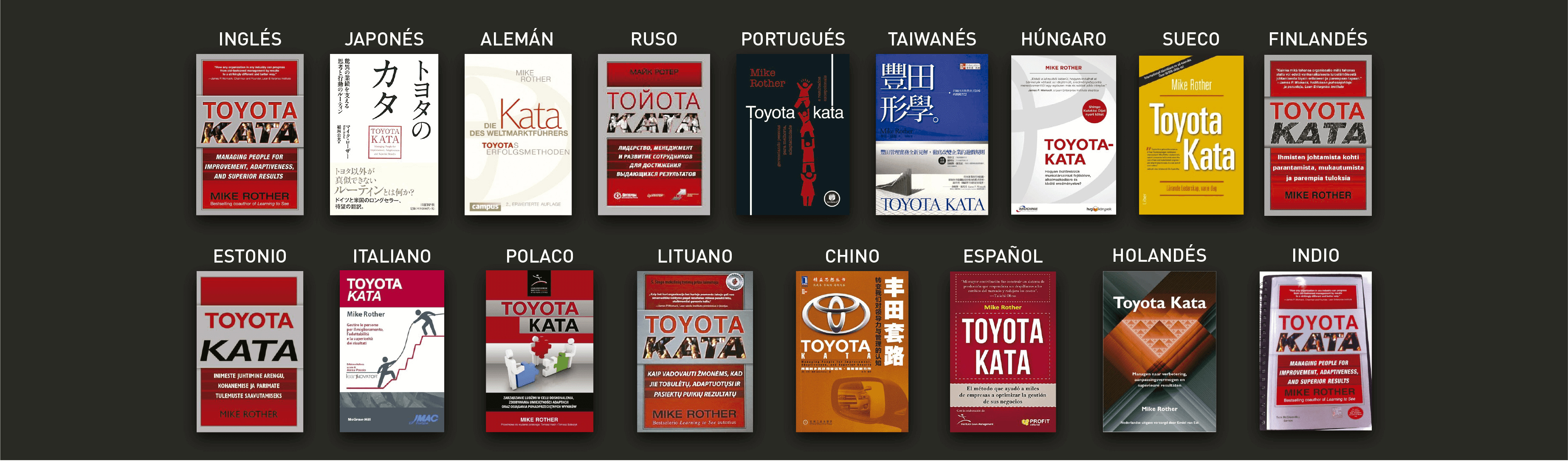

TRANSLATED TO 17 LANGUAGES

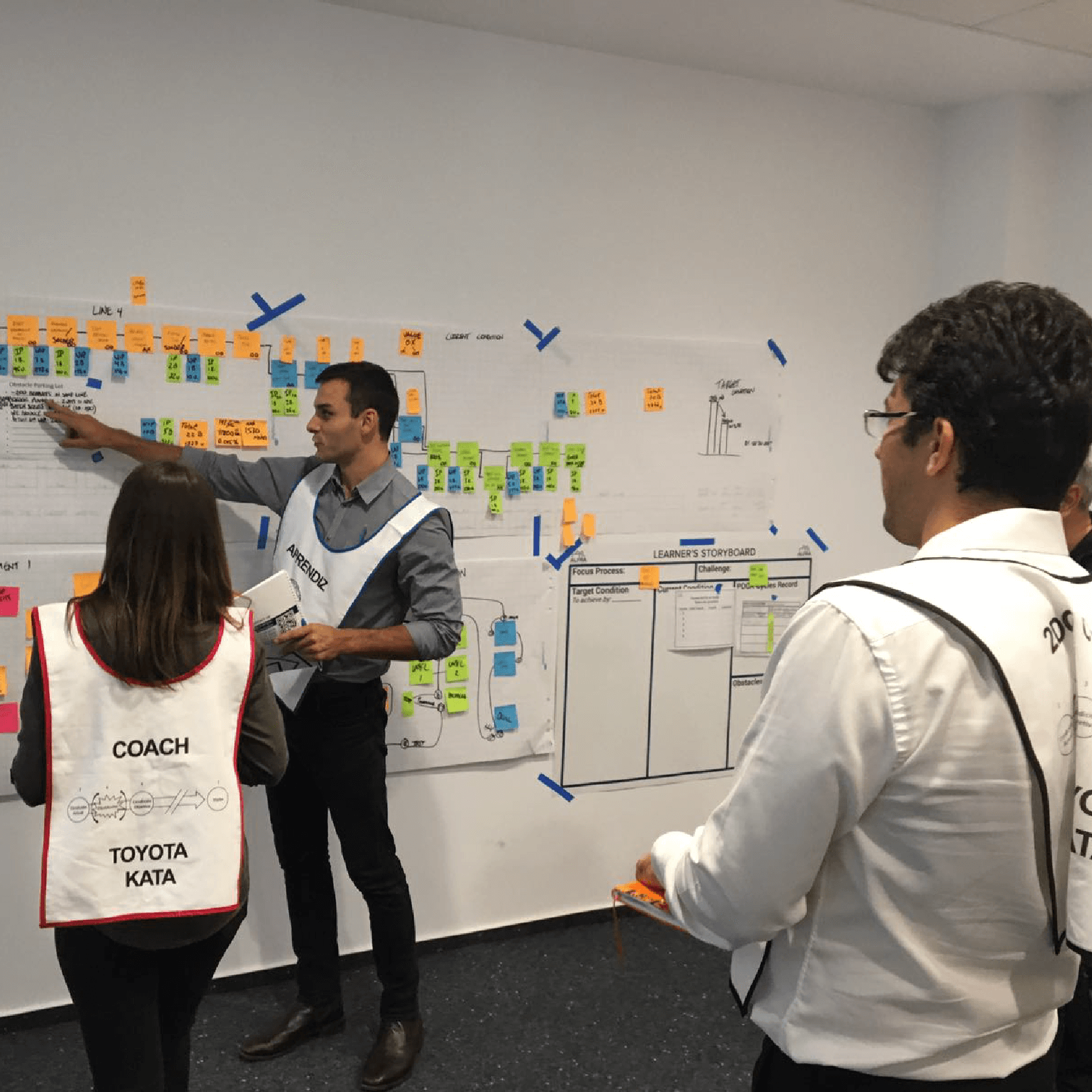

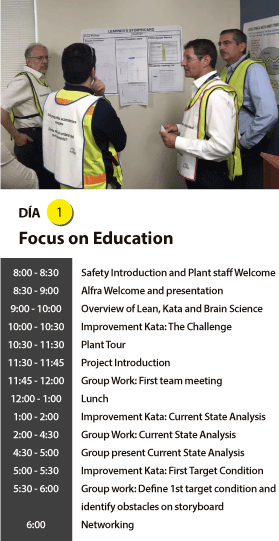

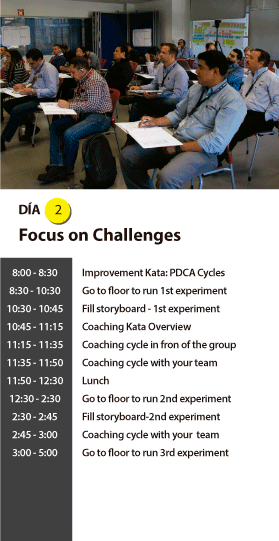

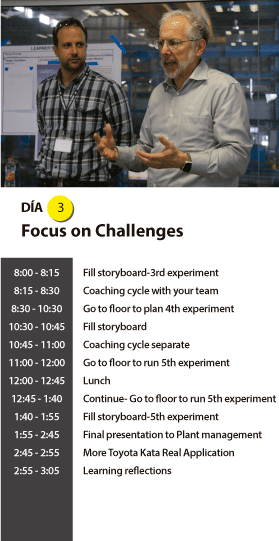

PROGRAM

INSTRUCTORS

LIDIA FLORES

Consultor Lean en ALFRA / Ha entrenado a más de 100 clientes en Lean Office, Lean Manufacturing y Toyota Kata, incluyendo Gerentes Generales.

Lidia has experience on the Toyota Way, Toyota Kata, Lean Leadership, Gemba Training for the last 5 years, she had been trained by Francisco Ocejo, Alfra Consulting Director Manager; Jeffrey Liker, author of the international best-seller The Toyota Way: 14 Management Principles; Ritshuo Shingo, who is Shigeo Shingo son and was the first president of JV Toyota China in 1998; Top Former Toyota Management. Lida Expertise is Lean Transformations under ALFRA Methodology: Hoshin Kanri, Daily KPI Management, Lean Operations, Lean Supply Chain, TPM, Problem Solving and Toyota Kata.

Lidia has trained more than 100 clients on Lean Manufacturing, including General Managers, Manufacturing engineer, Quality, Finance and Logistics. She also is Lean Office Instructor with experience on Logistics, Service company, Human Resources, Purchasing and Engineering change projects improvement.

Lidia´s principal customers and trainings:

Berry Global: Lean Transformation implementing Top Management to the each level closest to the Gemba in Quality, Opertions, Maintenance, Supply.

– Bitrón Automotive: Lean Transformation implementing Top Management to the each level closest to the Gemba in Quality, Opertions, Maintenance, Supply.

– Daimler Mercedes Benz, a bus assembly division; Lean Office and Toyota Kata training where we improve the engineering change applying Lean Office.

– San Mina, an Oil and Gas Company, Lean Office training and consulting, we reduce the total lead time from 10 to 5 days on the logistic chain including planning, purchasing, materials and engineering.

– DeAcero, wire division and steel. She participate on the DeAcero Production System, developing a continuous improvement system for logistic, purchasing, planning, shipping and production.

She has taught classes on Lean Manufacturing, Lean Logistics, Toyota Kata and Lean Office for different Universities as Tecnológico de Monterrey, UANL, UDEM, Universidad de Poza Rica, Universidad de Anáhuac, UPAEP.