EXECUTIVE LEAN

DATE & HOST

Upcoming Dates: To be determined

EXECUTIVE LEAN

Lean Leadership improves your and your organization’s results for a high-performance company that delivers sustainable results with Lean Philosophy. Lean leadership is the most frequently identified gap in the organization’s effort toward world-class excellence. This workshop will explore the broad role of Leadership in a cultural transformation, facilitate the identification of organizational gaps, and provide methodologies and practical processes to address them.

OBJECTIVES

- Learn how to involve management in a Lean Culture focused on processes and results.

- Understand how to align the KPIs (indicators) in all Lean levels.

- Understand how to manage the KPIs (indicators) in the different areas of the company.

- How to manage the development of Lean people at all levels.

- Learn pragmatic actions to improve your earnings and cash flow.

- Understanding why focusing on “cost cutting” in these difficult times is the wrong approach to building a Lean culture.

- Learn why "delegating Llean implementation" to others does not work, and can alter long-term results.

- Understand and implement processes and systems to maintain their a culture of improvement.

AIMED AT

- Top Management: CEO, COO, CFO, VPO,

- General Management.

- Plant Manager.

- General Managers.

- Management.

PROGRAM

| Day 1 | Day 2 | Day 3 |

|---|---|---|

|

|

|

Lean Leadership System- True North

Lean Work System – Fundamentals of the Daily Management Development System

Lean Development System – The Quality People Value Stream

Lean Management System – Cascading and Aligned Metrics Key Performance Indicator

|

Cascading and Aligned Metrics – Continued

Three Level Problem Solving

Gemba Problem Solving – KPI Improvement Review 8 Step Problem Solving

|

Gemba Problem Solving – Continued

Group Report Out – 8 Step Problem Solving for KPI Improvement

The Lean Development System: Connecting PROCESS & PEOPLE

Self Assessment Gap Analysis and Action Plan

Final Debrief and Dismiss |

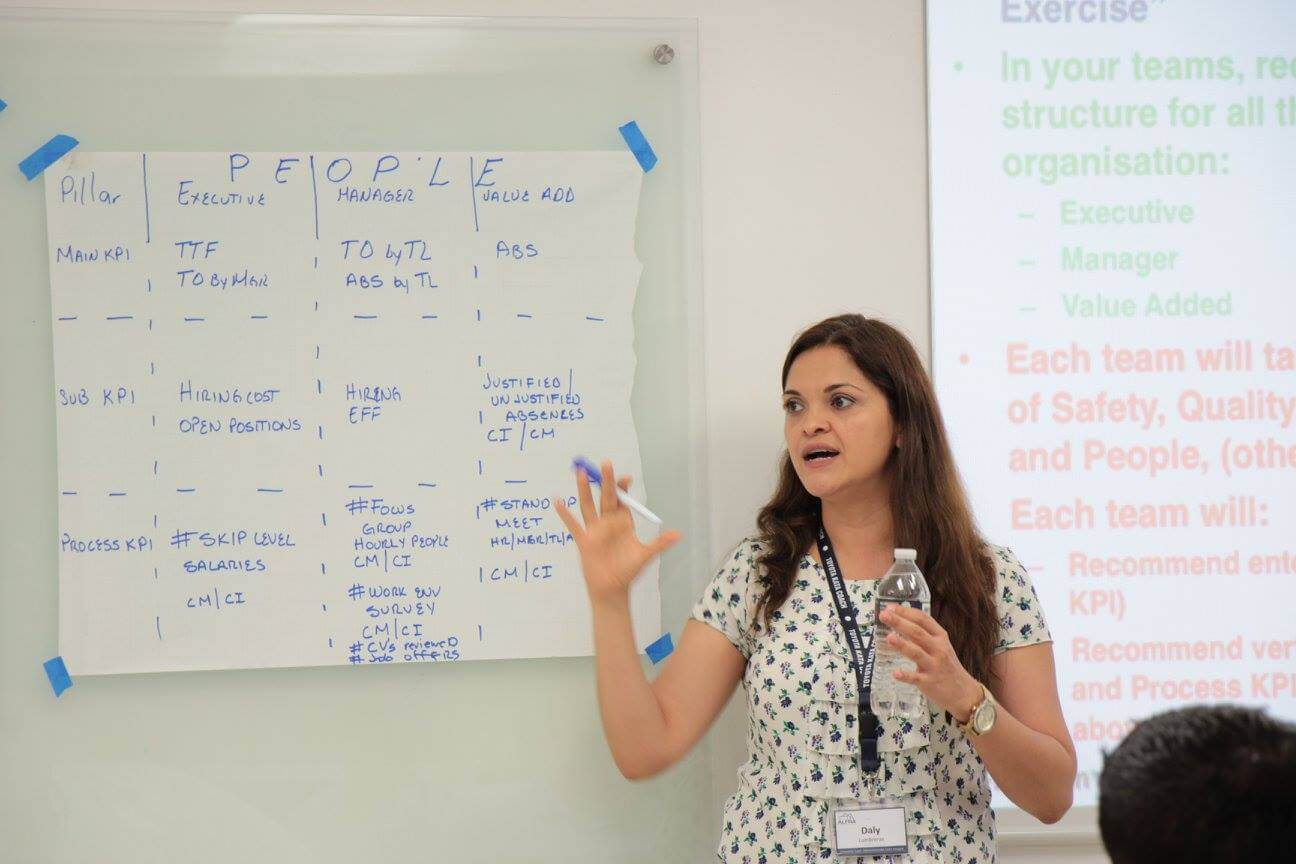

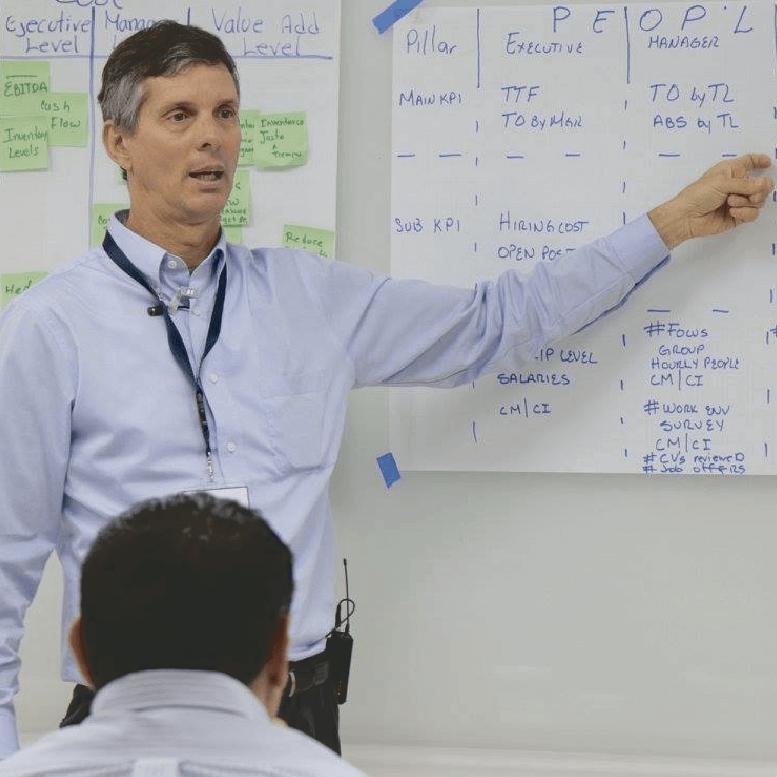

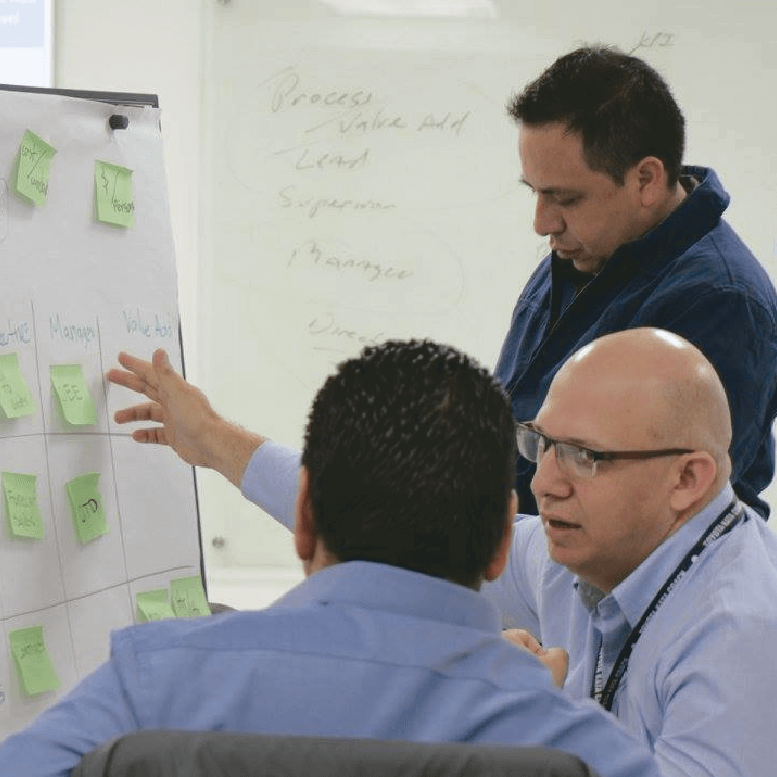

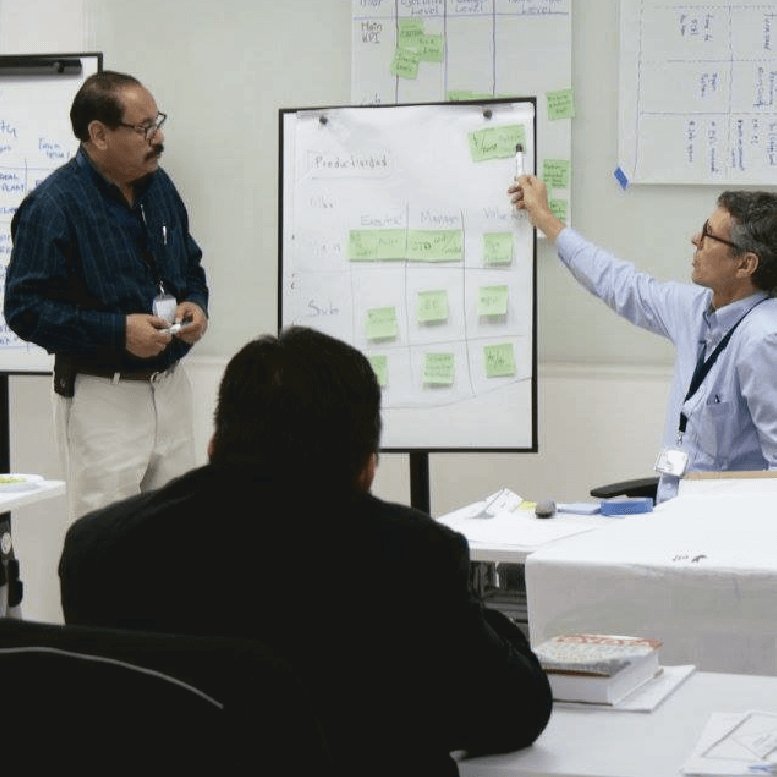

GALLERY OF PREVIOUS COURSES

INSTRUCTOR

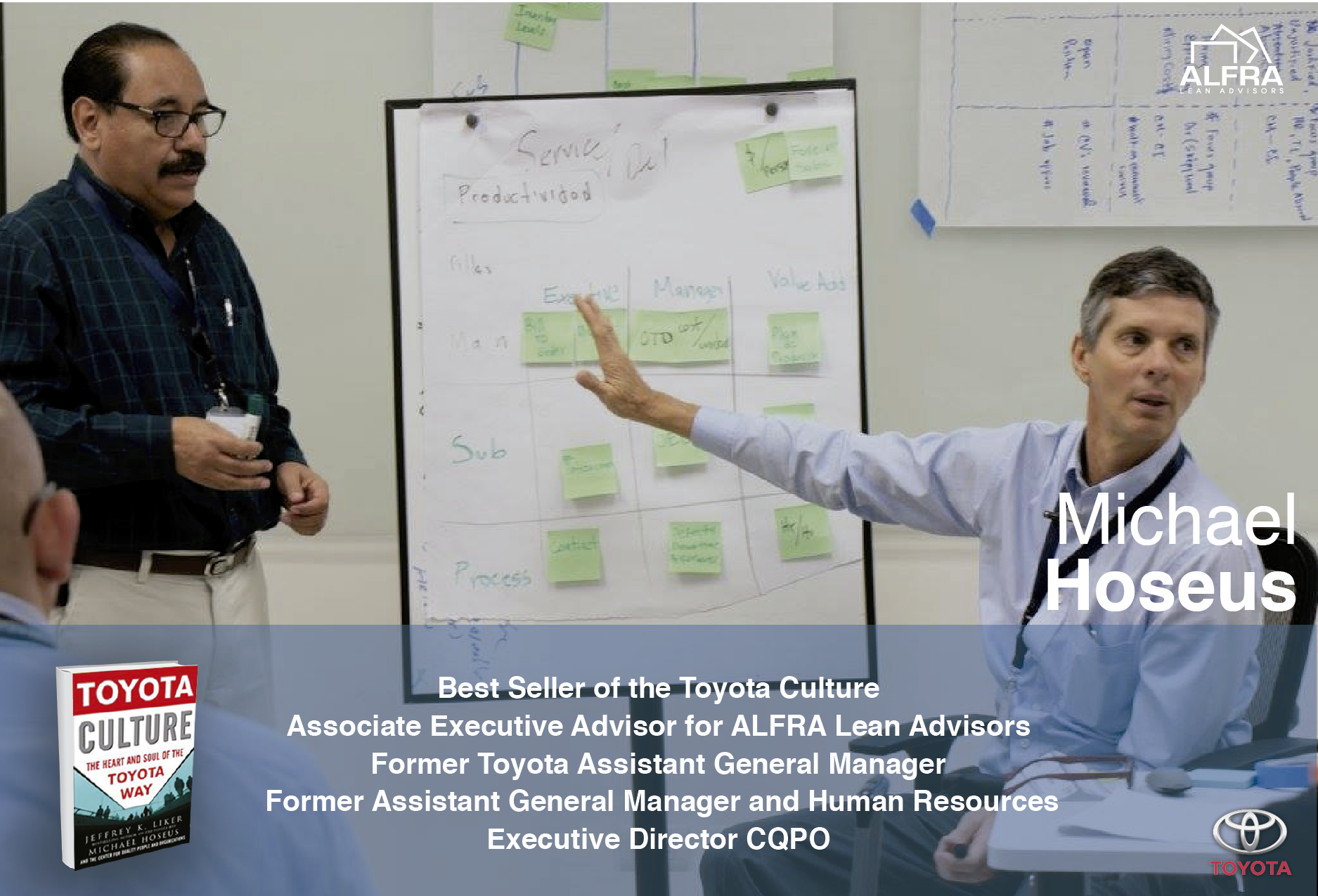

MICHAEL HOSEUS

ALFRA Toyota Team Director Former Executive Plant Manager of Toyota Kentucky

- Best Seller of the Toyota Culture

- Associate Executive Advisor for ALFRA Lean Advisors

- Former Toyota Assistant General Manager

- Former Assistant General Manager and Human Resources

- Executive Director CQPO

Mike is Executive Director for the Center for Quality People & Organizations (CQPO). Mike Hoseus brings both manufacturing operations and specialization in Human Resource experience to CQPO. CQPO is an organization developed in 1999 as a vision of Toyota Motor Manufacturing to share Lean Quality philosophy and human resource practices with education, business, and community organizations. CQPO current projects with Toyota include New Hire selection and training process, Team Leader and Group Leader post promotion training, Quality Circle Leader and Manager training, and Global Problem Solving for all levels. Mike is an adjunct professor with the University of Kentucky’s Lean Manufacturing Program. Mike is co author with Dr. Jeffery Liker (Author of the Toyota Way) of Toyota Culture. Mike is an adjunct professor with the University of Kentucky’s Center for Manufacturing and a member of the faculty of Lean Enterprise Institute. Mike is also president of Lean Culture Enterprises. Prior to CQPO, Mike was a corporate leader for 13 years at Toyota Motor Manufacturing’s Georgetown, Kentucky, plant both in Human Resources and Manufacturing. As Assistant General Manager in Human Resources, his responsibilities included personnel, safety, HR development, employee relations, benefits, training, and manufacturing/human resource teams for a plant of 8000 team members. His major initiative was development of the enhanced relationship between Human Resource and Manufacturing Mike’s operational responsibilities in manufacturing started in 1987 as a front line supervisor in vehicle assembly. This included all aspects of safety, quality, productivity, cost and morale for operations. With experience as Assembly Plant Manager and eventually Assistant General Manager, his responsibilities increased to include both assembly plants including operations, maintenance, and engineering. He is a Certified Trainer in Global Problem Solving & Waste Reduction, Standardized Work and Kaizen Events.

SERVICES INCLUDED

- Manual

- Coffee break & Lunch

- Course Certificate.

- Simultaneous translation service (additional cost if required)

- Exclusive to 25 participants