INVENTORY REDUCTION

THROUGH THE TOYOTA WAY

DATE & LOCATION

To define

BY CONCLUDING THIS COURSE YOU WILL ACHIEVE:

- Understand the concepts of Lean applied in Supply Chain to operate as a dynamic and effective system.

- Have an overview of the application of Lean principles in different scenarios to reduce inventories of MP, WIP, PT.

- Carry out an analysis of the logistic and productive processes that identifies areas of opportunity around inventories.

Since the inventory is an investment that has not yet materialized in utilities, Tools and Lean Approaches have been developed to predict and control the levels of inventory for a healthy management of them. The Program will review the various elements that define and trigger inventory levels and how Toyota uses them.

OBJECTIVES

-

The first part covers the general concepts of Lean applied in Supply Chains, Supply Chain Maps to identify areas of opportunity at the systemic level and practical applications of the processes of the participants.

The first part covers the general concepts of Lean applied in Supply Chains, Supply Chain Maps to identify areas of opportunity at the systemic level and practical applications of the processes of the participants.

- The second part consists of the revision of the approaches and tools of Lean with Provision, Plant and Finished Product that anticipate and reduce inventory amounts.

- The Identification of Opportunities within the processes, generating Design of the Future Map, and landing in a Strategic Plan of Action. Understanding Lean for the achievement of the Reduction of Inventories of its Company.

AIMED AT

Managers and Materials Engineers, Logistics, Supply Chain, Planning, Purchasing, Warehousing, Production, Manufacturing, Continuous Improvement.

PROGRAM

| Day 1 | Day 2 | Day 3 |

|---|---|---|

|

|

|

|

|

|

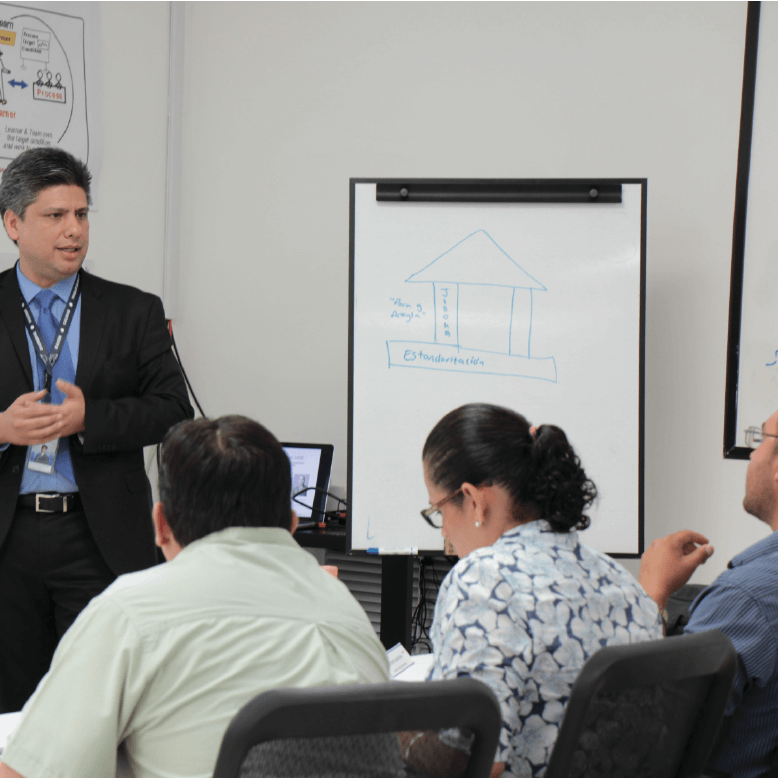

INSTRUCTOR

GUSTAVO VARELA

IMA, MBA, MBB. Director División de Consultoría

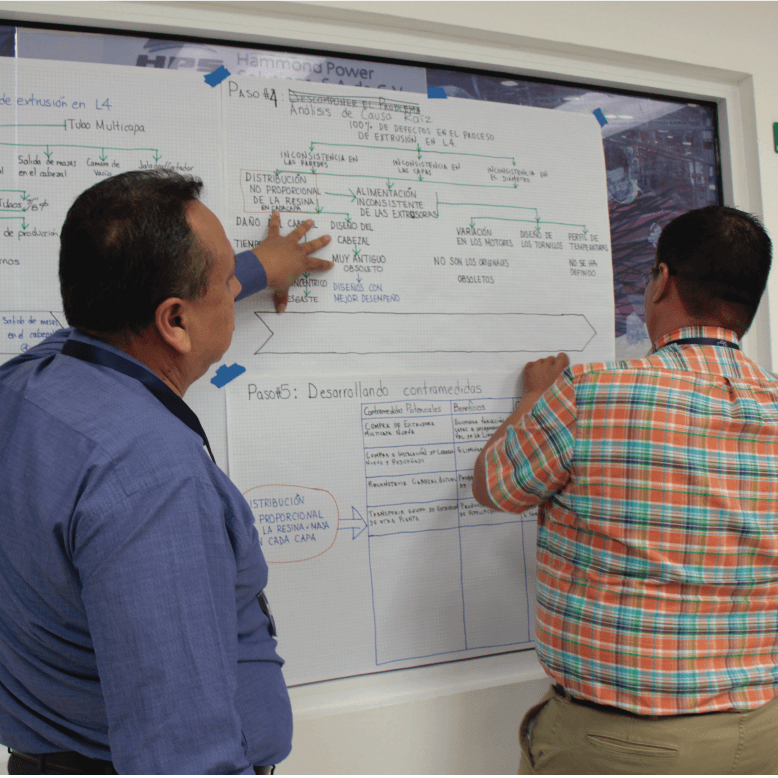

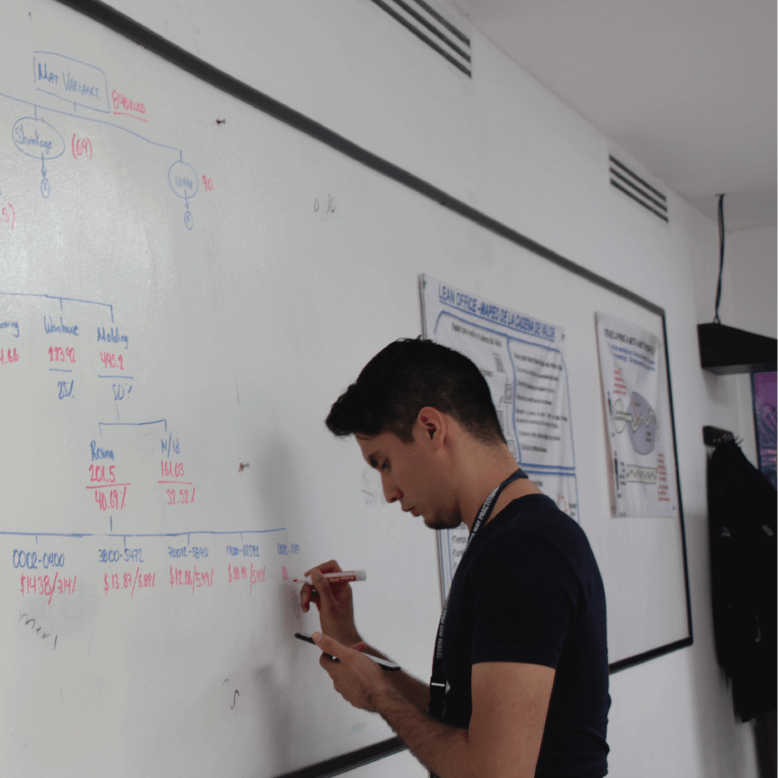

Based on his broad experience, Gustavo is expert applying a suitable approach for Continuous Improvement needed on the different organizations from a Business results optic, becoming an effective Coach for Top Management and support for The Toyota Way roles. Gustavo has learned The Toyota Way directly from its Author, Dr. Jeff Liker, and has applied it on Gemba as a Team with many Executives from Toyota specialized on General Management, TPM, Lean Mfg Tools, and Supply Chain. Gustavo has taught the Toyota Production System at all organizational levels and has applied over 50 companies of different sizes: Lean Leadership Systems (Hoshin Kanri, FMDS, and 8-Step Problem Solving), Toyota Kata for development, Supply Chain Management, TPM, Lean Manufacturing tools (5S’s, SW, SMED, Jidoka, Poka Yoke, Heijunka, JIT, etc.), and Lean Office approach. On Six Sigma, Gustavo as Master Black Belt has trained and certified +500 Black Belts, Green Belts, and Yellow Belts. Gustavo has +20 years of experience on Continuous Improvement, Manufacturing, Process Engineering and Quality in large companies: Motor Wheel (Automotive), Kodak, Philips, Daltile, American Standard. He has +12 years of experience as Vice/President Staff as Continuous Improvement Director for American Standard México and Master Black Belt Champion for Daltile México. He has deployed programs that have achieved +$110 Million USD in savings with +3,000 projects on all departments: R&D, Engineering, Manufacturing, Maintenance, Quality, Logistics, Supply Chain, Sales, Marketing, Finance, HR, Energy. Over his 22 years experience, Gustavo has been exposed to many different organizations applying suitable Lean approaches on a variety of systems with diversity on leadership styles.

SERVICES INCLUDED

- Diploma of Training.

- Digital Manual

- Implementation formats and templates for Lean systems and tools.

- Quality Coffee Break

- Lunch included

- Certificate of training