Are you looking to develop yourself professionally?

We have training for you!

The “Training plan for successful lean professionals” program is designed to form the most successful Lean leaders of the next generation. Participants receive first-rate training with our national and International consultants with more than 30 years of experience inside and outside Toyota.

LEAN TRAINING

- Lean Manufacturing Online

- Toyota Way Online

- Coaching Management Toyota Kata Online

- Lean Office Online

- Six Sigma Black Belt Online

REQUIREMENTS

- To be enrolled student of any engineering from 5th semester with an grade point average equal or superior to 80.

- Study all programs in a period not longer than two years.

BENEFITS

- First level training with scholarships of up to 95%.

- Increase the curricular value of your engineering profile.

- Possibility to connect with more than 1500 companies.

WE HAVE COLLABORATED WITH THE LARGEST MANUFACTURING COMPANIES AND SERVICES AROUND THE WORLD.

- Automobile and components

- Electric equipment

- Containers & Packaging

- Aerospace

- Textiles, Clothing and Luxury Goods

- Food, Beverage and Tobacco

- Pharmaceutical Products

- Banks

- Chemical Products

- Construction Materials

- Customer Service

- Retail

THESE UNIVERSITIES TRUST US

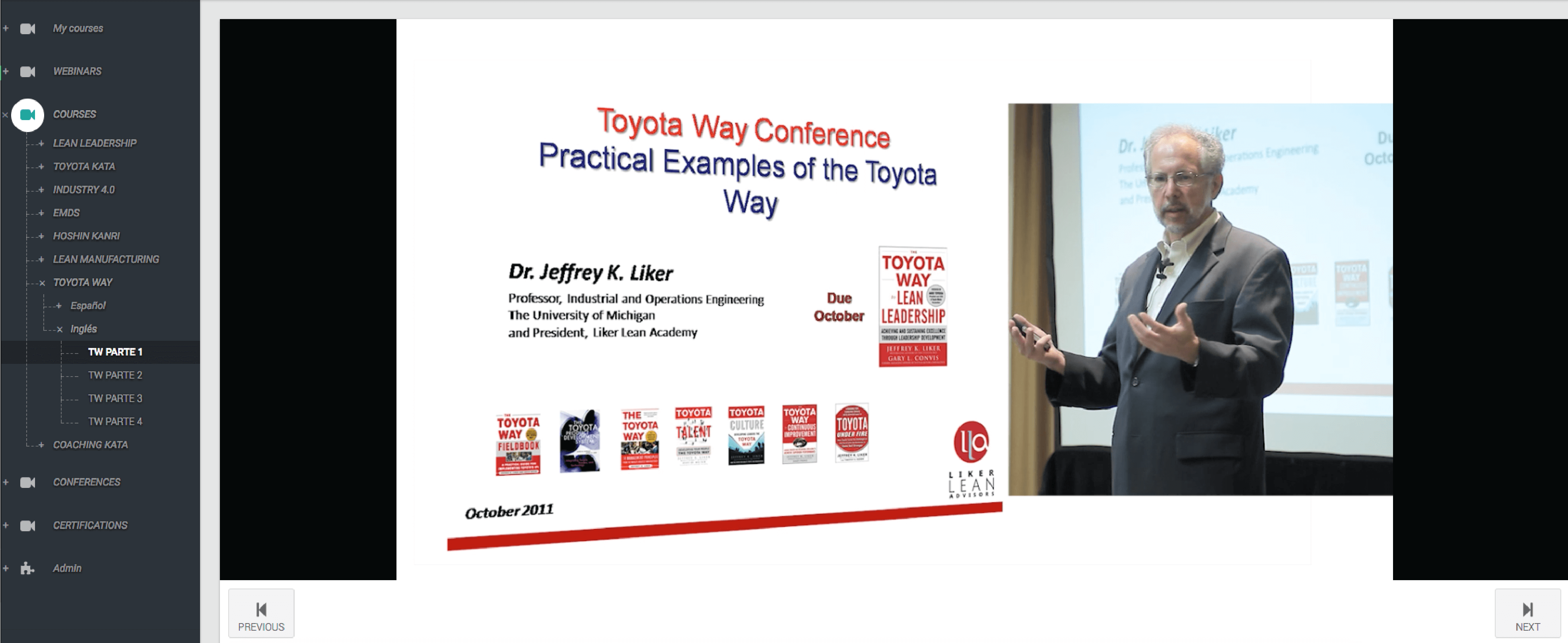

Online Platform Visualization

The image shown below represents the Toyota Way course taught by Jefferey Liker “Best Seller of the Toyota Way”.

– Programs include videos, exercises, and final exam, which requires a score of 80 points or more to pass the course.

– At the end of each program, an electronic diploma signed by the instructor will be sent by email, which guarantees that yousuccessfully completed it.

– Payment can be made by program or by complete plan.

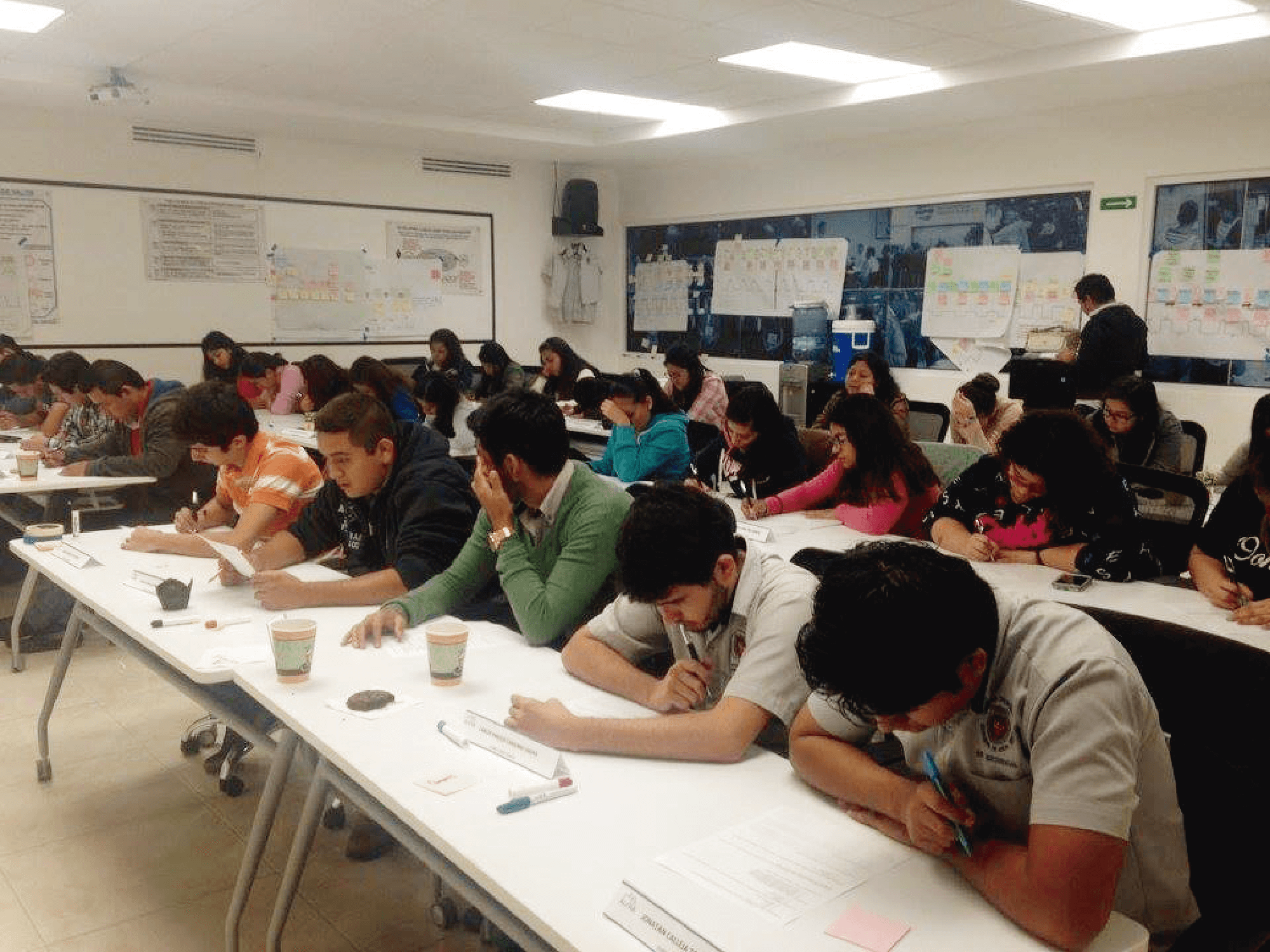

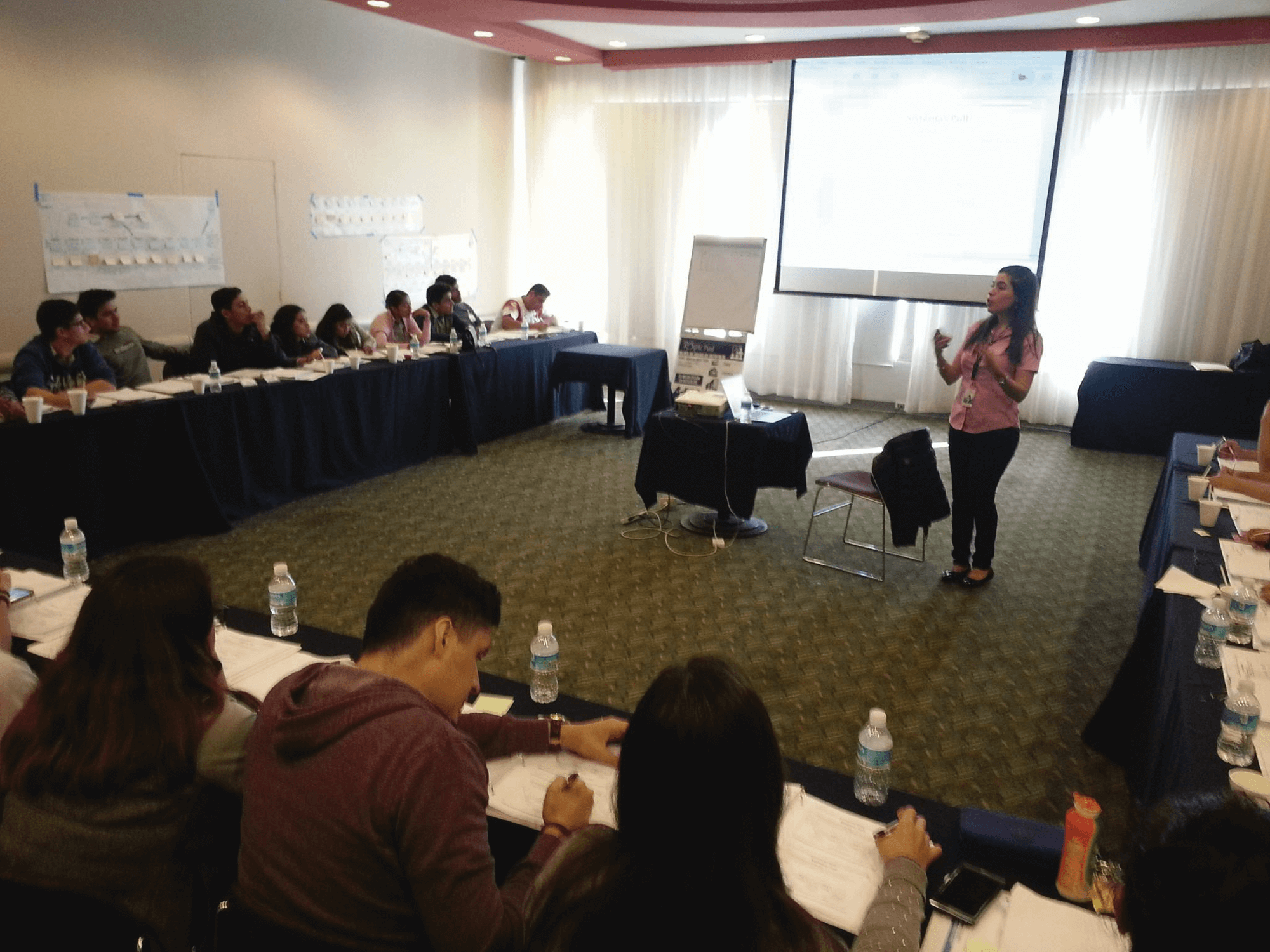

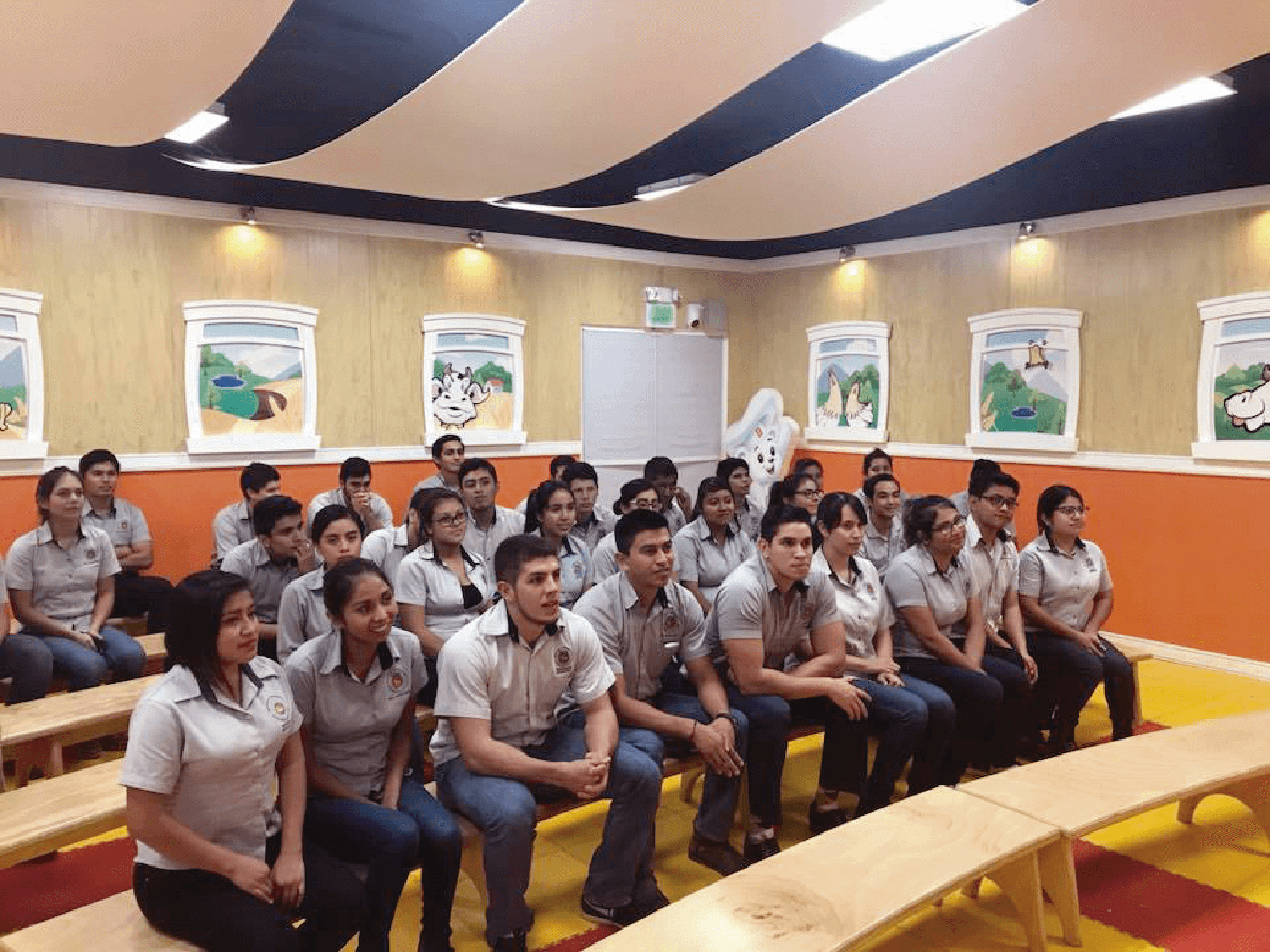

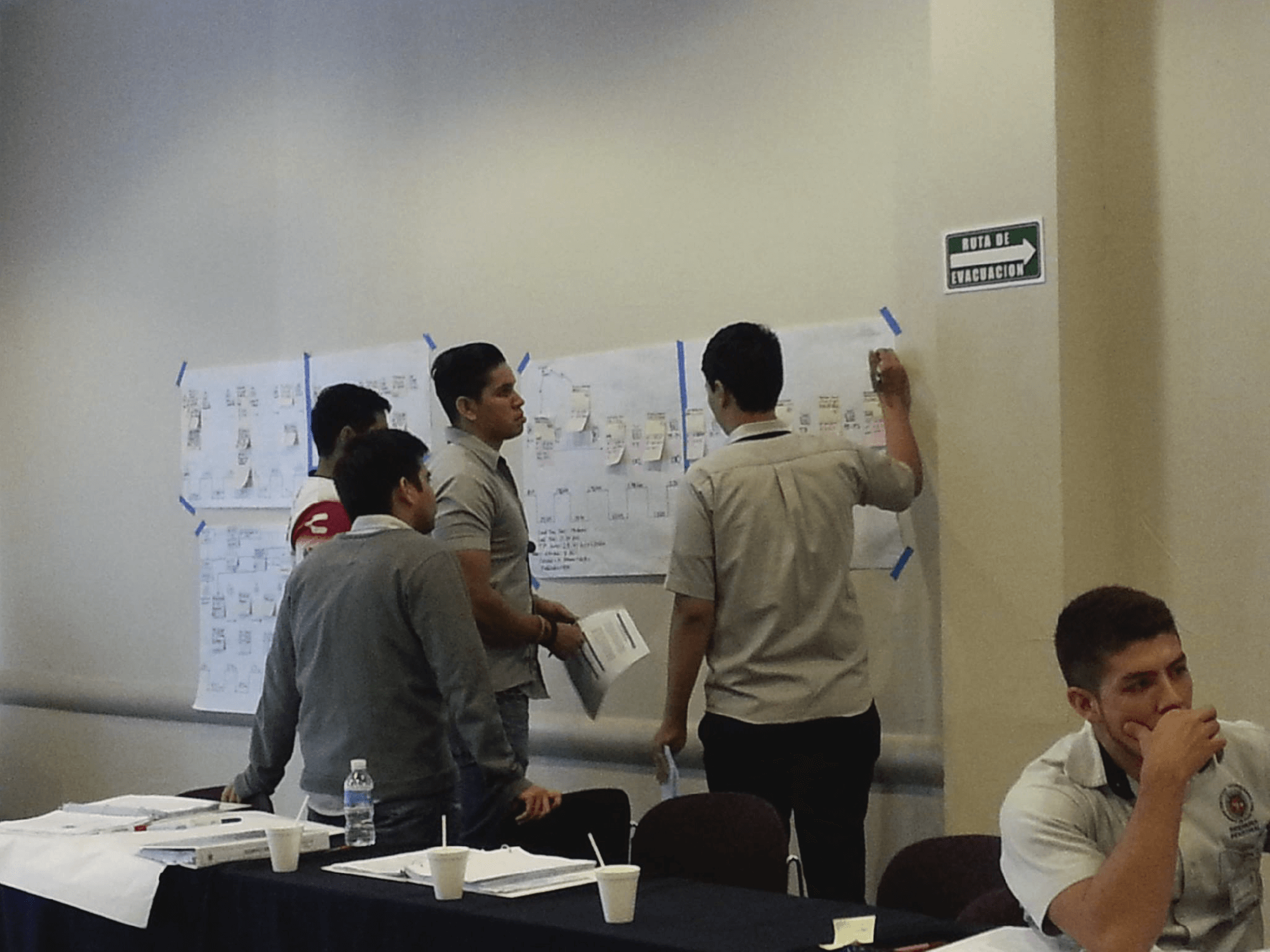

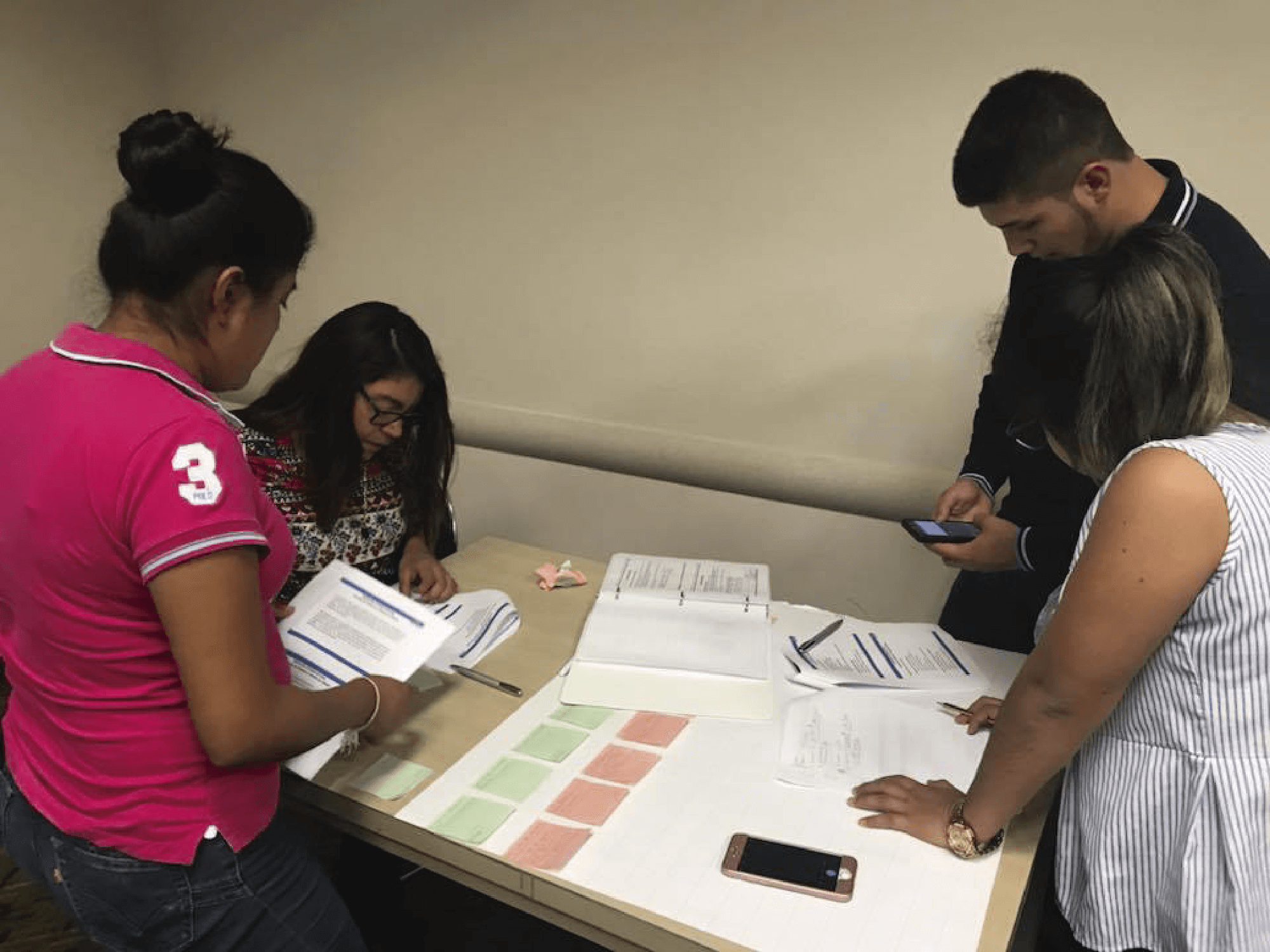

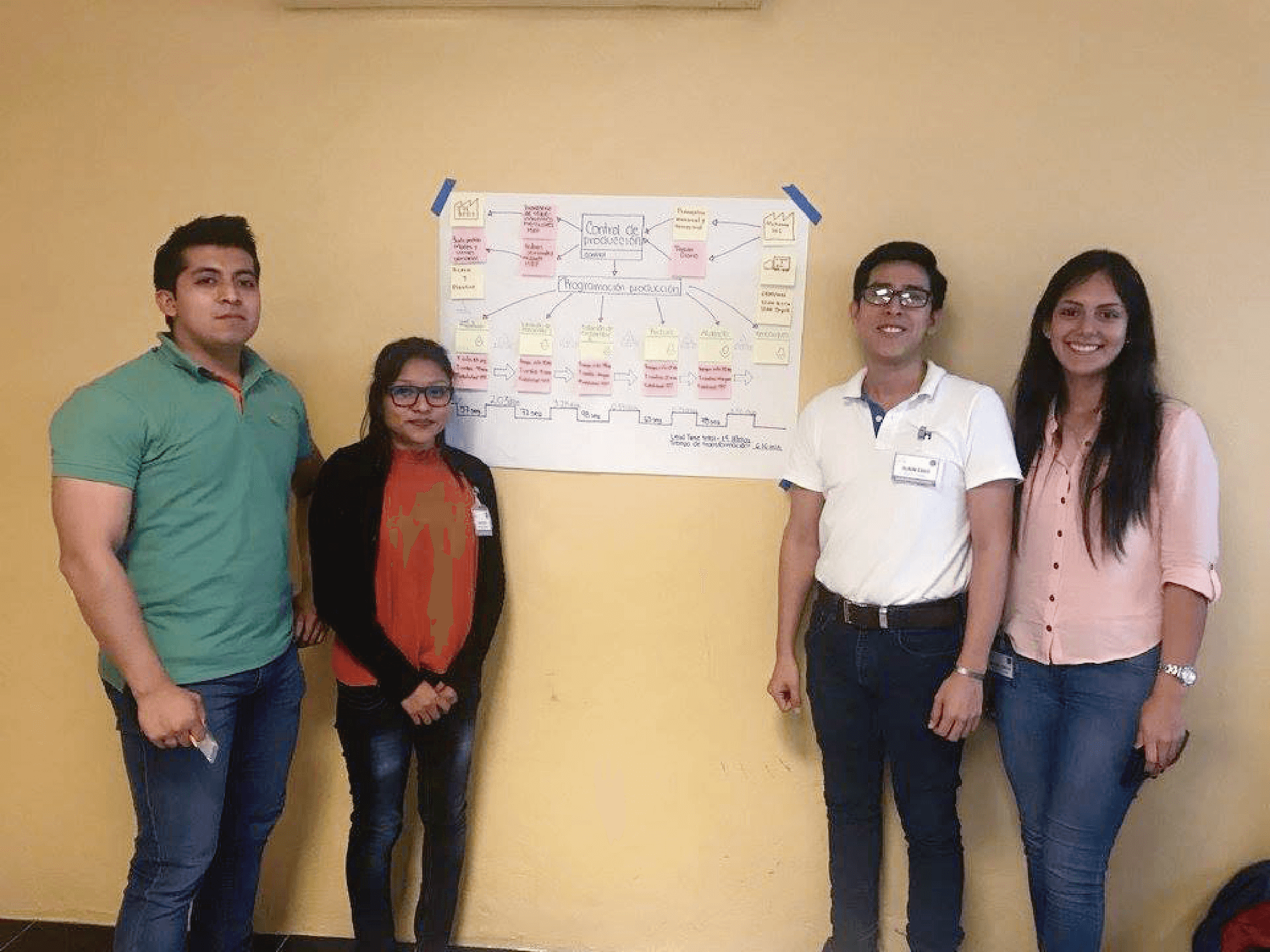

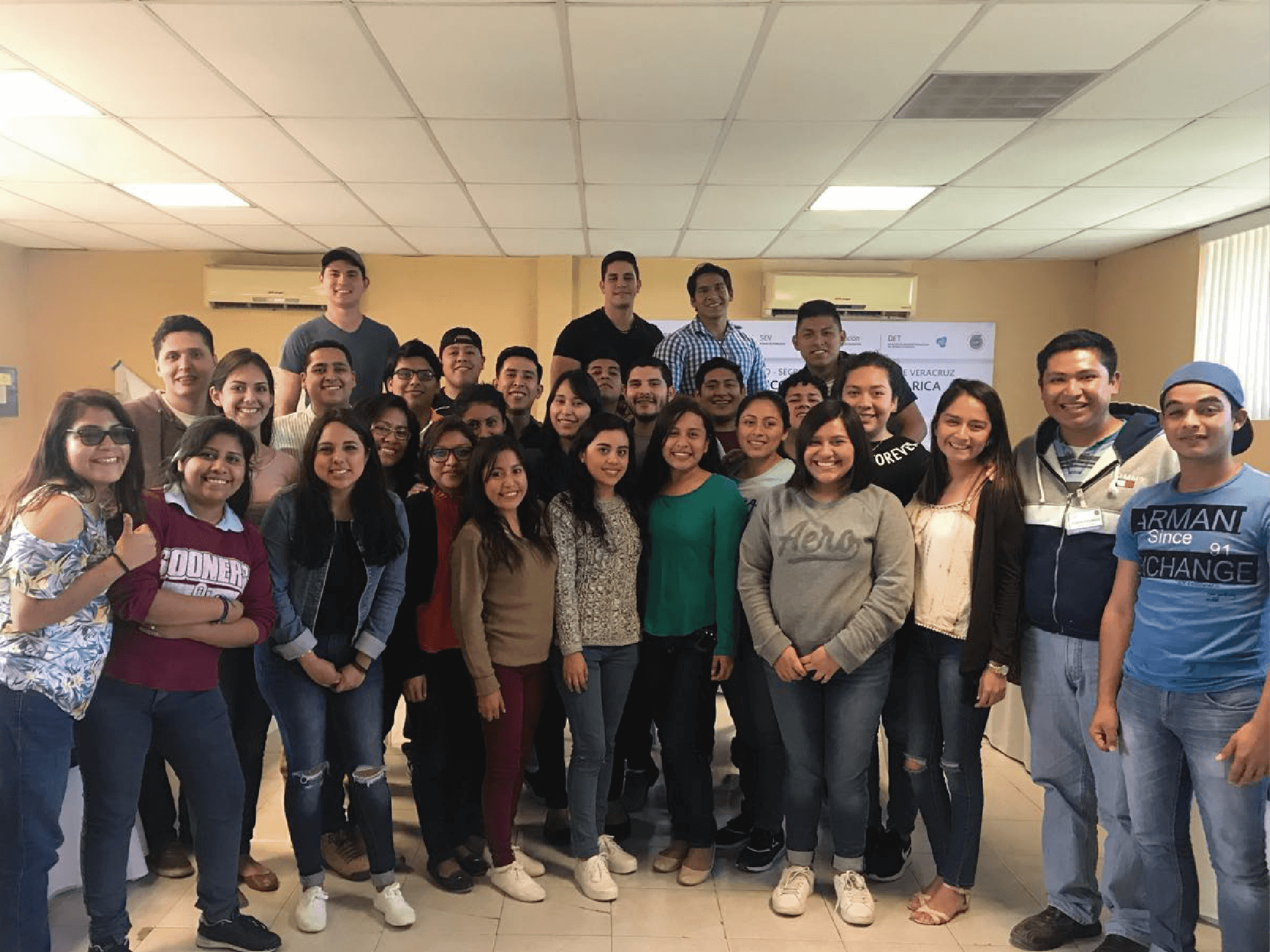

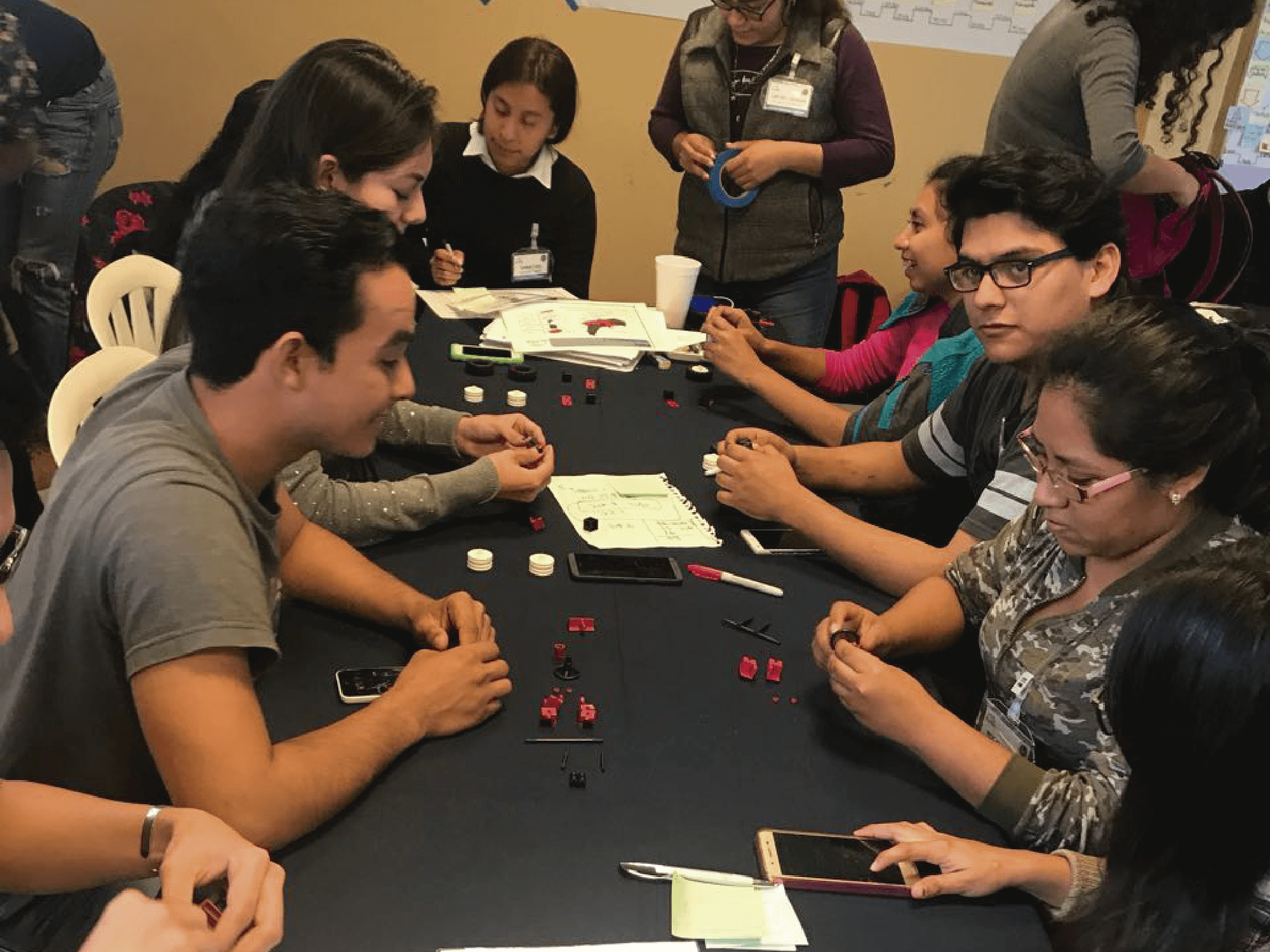

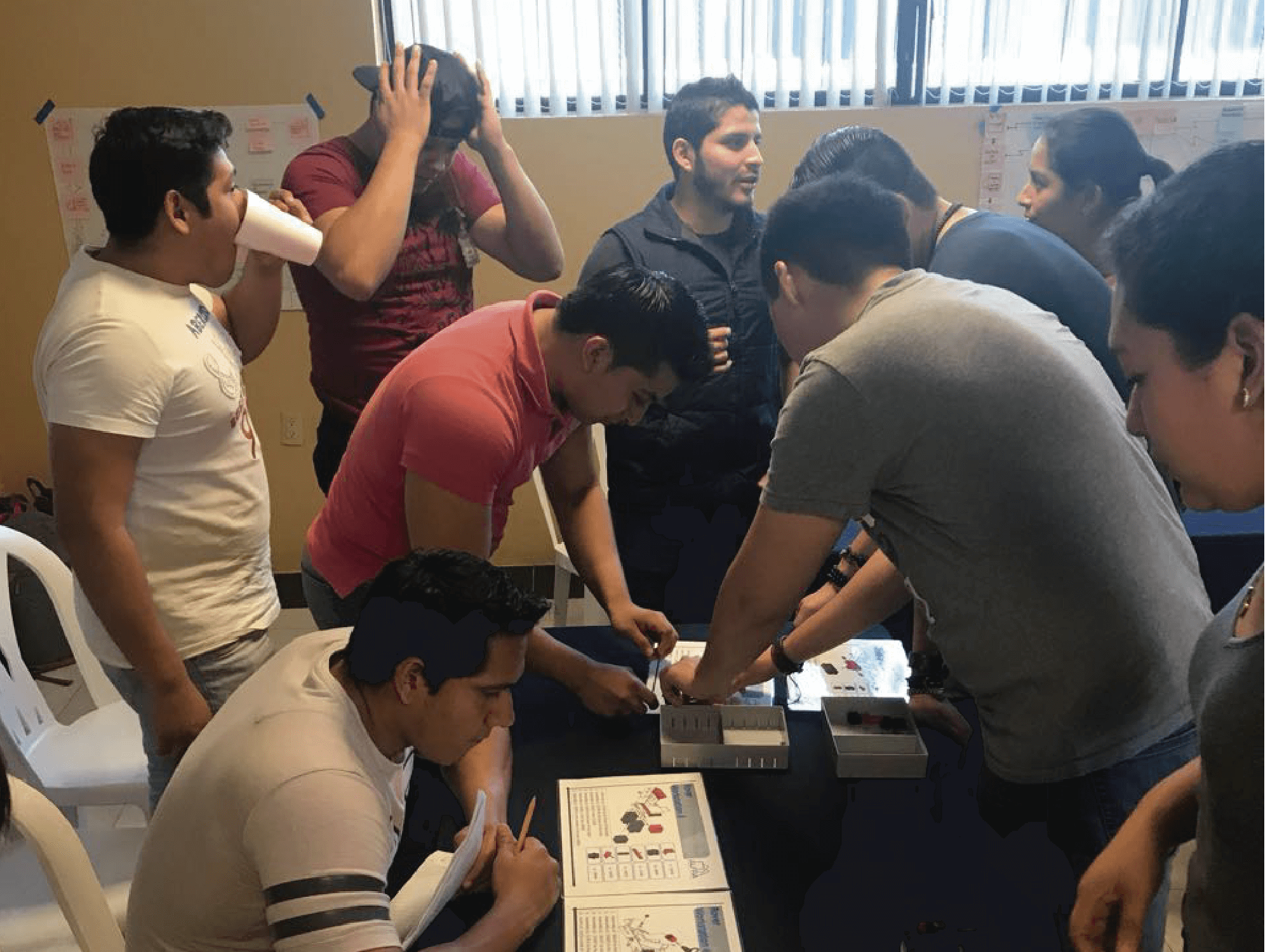

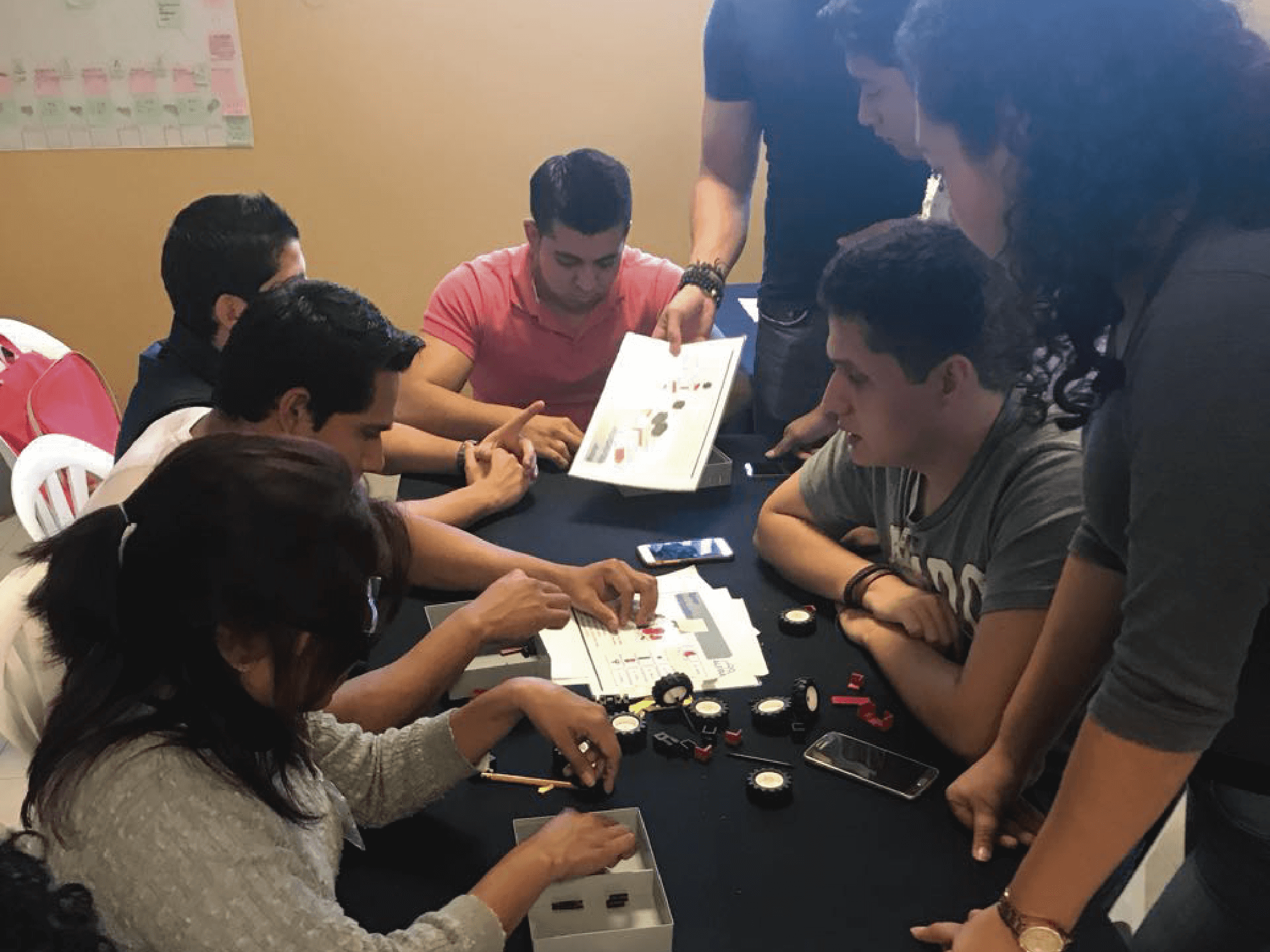

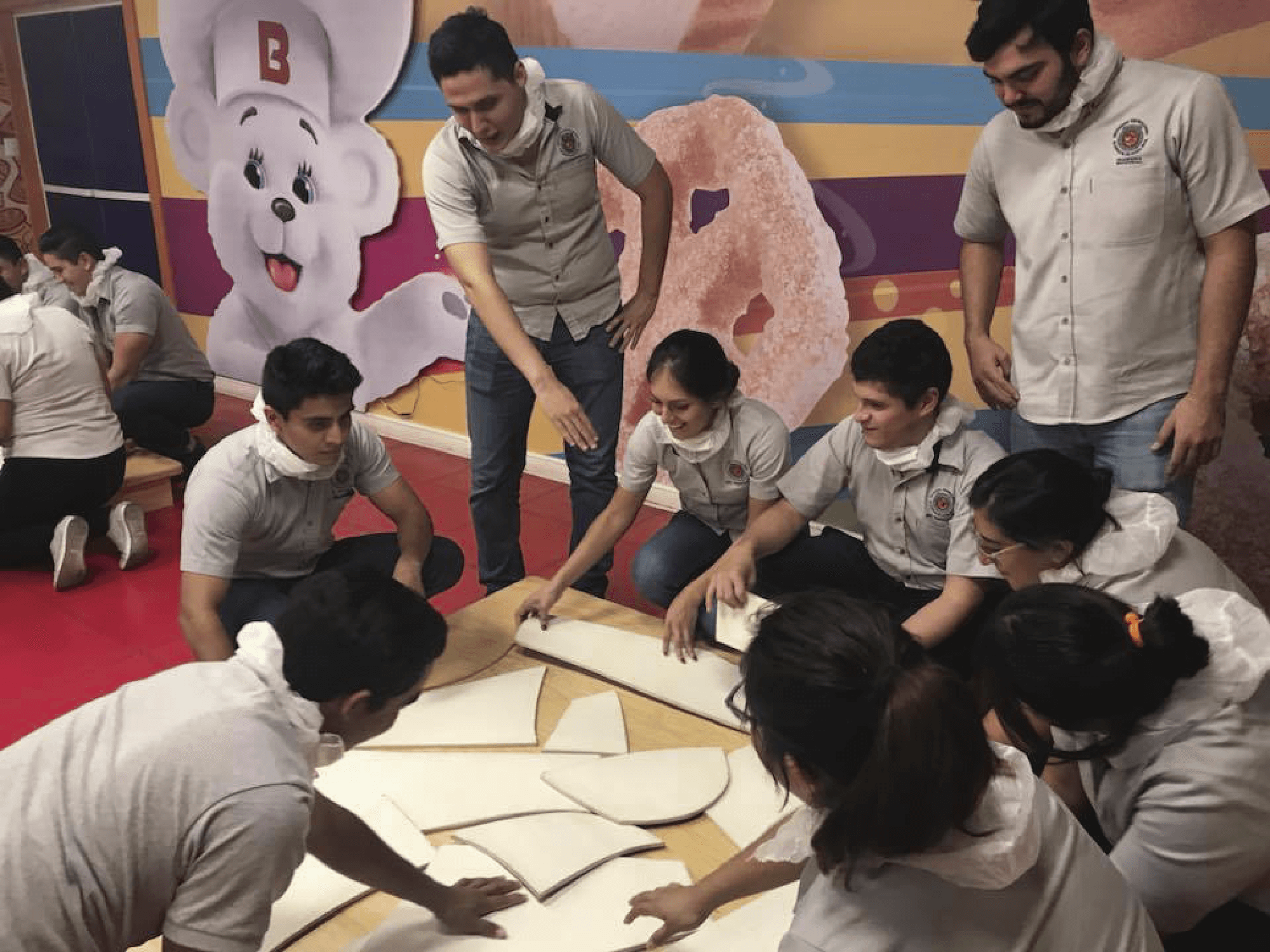

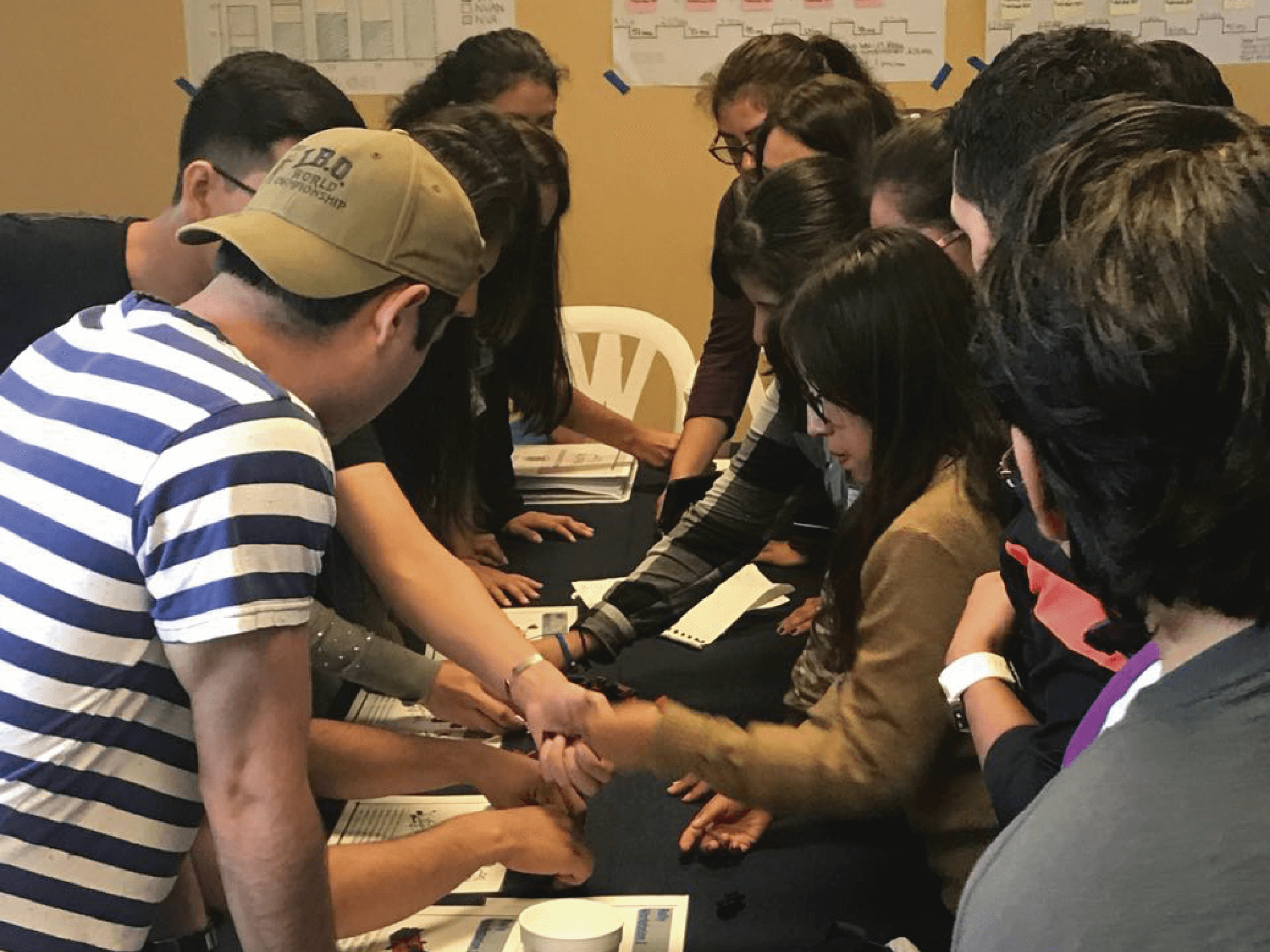

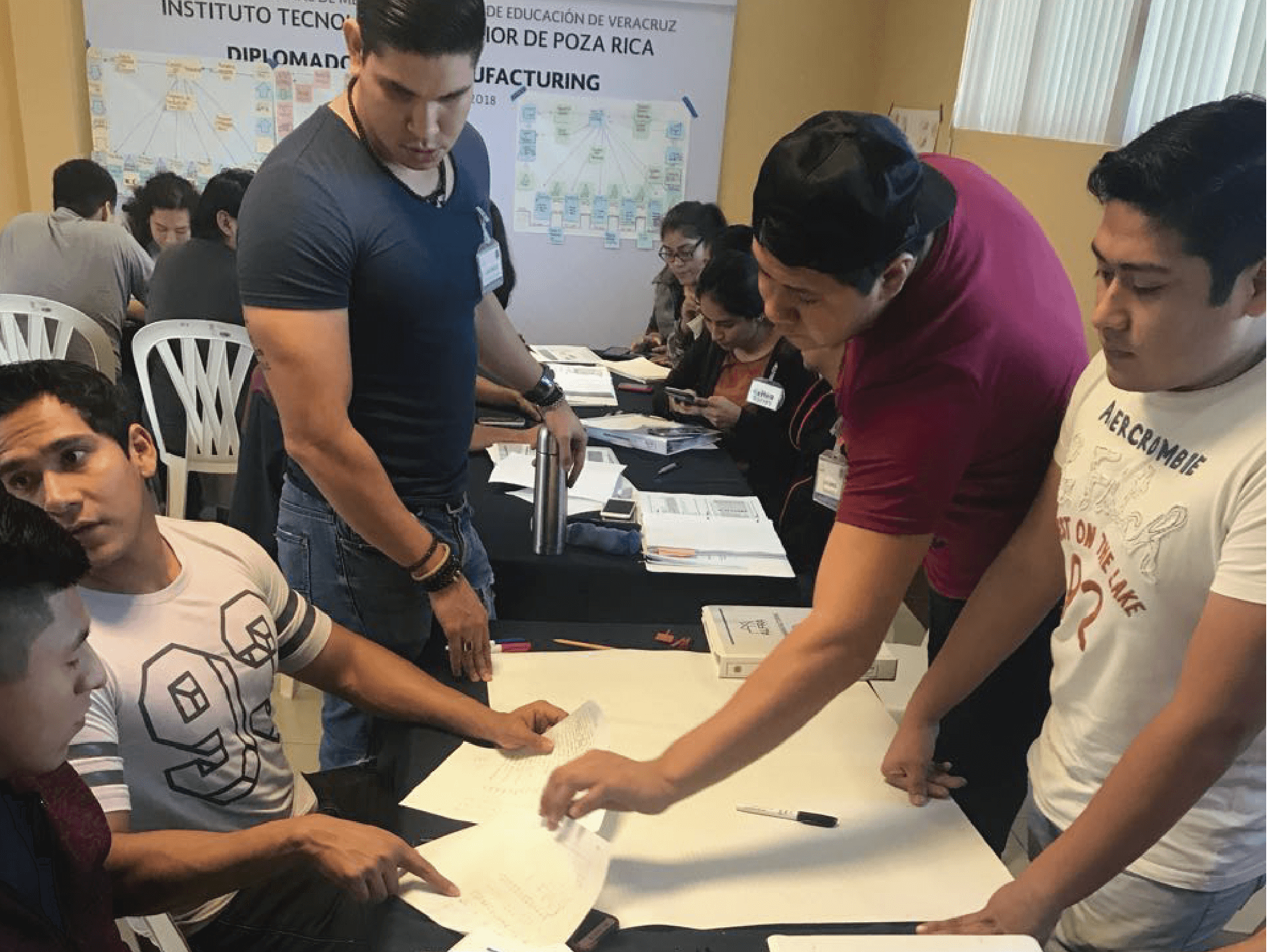

Galería de cursos anteriores

LEAN TRAINING

TOYOTA WAY

LEAN MANUFACTURING

LEAN OFFICE

SIX SIGMA BLACK BELT

COACHING MANAGEMENT TOYOTA KATA

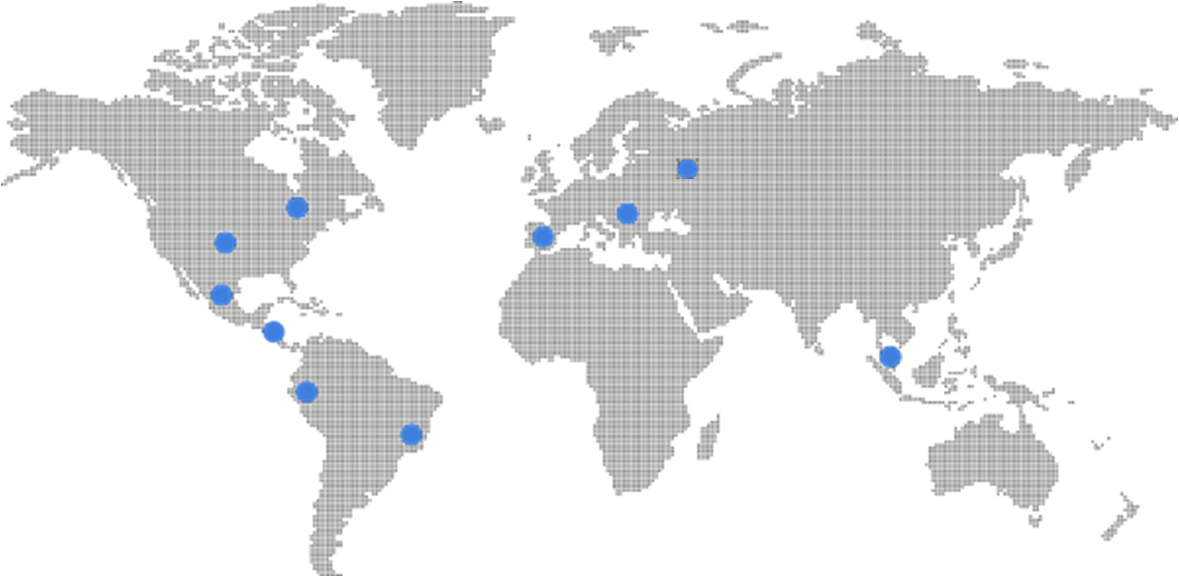

WORLDWIDE PRESENCE

INFORMATION CONTACT:

Lidia Flores Guijarro Lean Consultant for ALFRA Lean Advisors Virtual University Manager

- E-mail: lidia.flores@alfraleanadvisors.com

- HC Office: +52 81 8058 0738 Cel: +52 (811) 945 1894