TOYOTA KATA IN FIELD

IMPROVE THE PERFORMANCE OF YOUR PROCESSES!

COURSE FOCUSED TO IMPROVE OEE: QUALITY, SPEED, AVAILABILITY, COST, DELIVERY, HR AND OTHER BUSINESS APPLICATIONS.

DATE & HOST

November 5th to 7th

Monterrey, Mexico

Monterrey, Mexico

When you finish Toyota Kata you will:

- Start the process of implementing the Toyota Kata in your company.

- Apply scientific thinking in a way that applies to Toyota to achieve great challenges.

- Be able to maintain a constant leadership of the Leader and the apprentice, improve week-by-week with proven results in hundreds of companies.

- Become a leader in the creation of in a learning environment and drive continuous improvement.

OBJECTIVES

- Learn how to develop strong challenges for companies and departments.

- Learn to designe_ne patterns of current operations in the company (understand the process)

- Learn to devise desired patterns that deliver the right result (focus on the process)

- Learn to visualize where the threshold of knowledge is and avoid moving to the objective operation pattern (Desired process)

- Learn how to perform experiments, observe results, and use applications to move forward.

- Understand when a desired condition has been reached, and to define new operating patterns for better results.

- Teach to reflect on the processes of experimentation, learning and applications.

AIMED AT:

- Vice Presidents

- Directors of Operations or General Managers

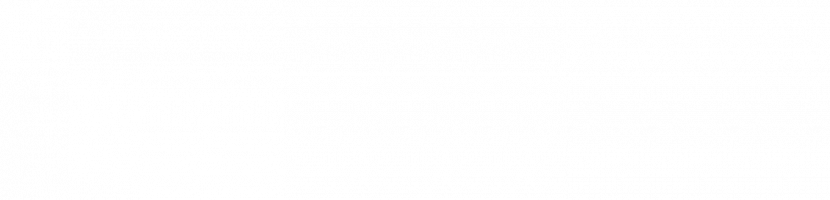

PROGRAM

INSTRUCTORS

FRANCISCO OCEJO

Director general ALFRA Embajador Toyota Kata México Experiencia Toyota Kata Europa, Norte América y Sudamérica.

Francisco Ocejo is leading Alfra Lean Advisors a Consulting firm with over 1,500 customers companies from many countries. He also is the Vice President of Alfra Institute, a education organization to develop the top Management under a Lean MBA degree formed with Former Toyota executives and Top worldwide Management.

He has been learning, applying, and teaching the Toyota Production System in Canada, USA, Mexico, Latin America & Europe. He has taught and applied Lean from the senior management level to the operational levels closest to Gemba fro over 150 companies from international corporations, to mid-size and small family businesses from diferent industry sectors such as: Service, Logistics, Aerospace, Automotive, Electronic, Bank, Ceramic, Education, Defense Electronic, Food & Beverage, Gas & Oil, Electric Manufacturing, and several manufacturing sectors.

Francisco is a Toyota Kata Ambassador and Pioneer to spread the Toyota Kata in Mexico, he has been applying TK with his colleague Dr. Jeff Liker ( author of the best seller the toyota Way) and many other Coaches in companies with the hieghest TPS people development.

For over 5 years he has been constantly trained by the Best Seller “Toyota Way (800 hrs),” the Ex President of JV Toyota China Mr Shingo (360 hrs), and various Toyota top Management ( + 1000 hrs).

His best expertise is in: Coaching Toyota Kata, Lean Manufacturing,Lean Office, Lean Culture and Business Transformation.

He is an Industrial and Systems Engineering at the Monterrey Technical Institute. He has taught classes for students in over 15 Universities, lecturing in various Congresses in Mexico. Certified as Black Belt Six Sigma.

He is an Industrial and Systems Engineering at the Monterrey Technical Institute. He has taught classes for students in over 15 Universities, lecturing in various Congresses in Mexico. Certified as Black Belt Six Sigma at Institution of Industrial Engineers, and the Theory of Constraints and Thinking Process at the EGADE of the Monterrey Technical Institute.

Francisco is a former Celestica leader & manager of the Lean Culture Transformation, with BlackBerry (RIM), Palm, HTC as Principals customers, with sales of over 1 billion dollars. This transformation.

LIDIA FLORES

Has trained and coached more than 100 clients on Lean Office, Lean Manufacturing, and Toyota Kata Instructor including General Managers. Participated on the DeAcero Production System development. Lean Office in field training and implementation to potentially reduce lead time from 16 to 10 days on San Mina.

Lidia has experience on the Toyota Way, Toyota Kata, Lean Leadership, Gemba Training for the last 5 years, she had been trained by Francisco Ocejo, Alfra Consulting Director Manager; Jeffrey Liker, author of the international best-seller The Toyota Way: 14 Management Principles; Ritshuo Shingo, who is Shigeo Shingo son and was the first president of JV Toyota China in 1998; Top Former Toyota Management. Lida Expertise is Lean Transformations under ALFRA Methodology: Hoshin Kanri, Daily KPI Management, Lean Operations, Lean Supply Chain, TPM, Problem Solving and Toyota Kata.

Lidia has trained more than 100 clients on Lean Manufacturing, including General Managers, Manufacturing engineer, Quality, Finance and Logistics. She also is Lean Office Instructor with experience on Logistics, Service company, Human Resources, Purchasing and Engineering change projects improvement.

Lidia´s principal customers and trainings:

–Berry Global: Lean Transformation implementing Top Management to the each level closest to the Gemba in Quality, Opertions, Maintenance, Supply.

— Bitrón Automotive: Lean Transformation implementing Top Management to the each level closest to the Gemba in Quality, Opertions, Maintenance, Supply.

– Daimler Mercedes Benz, a bus assembly division; Lean Office and Toyota Kata training where we improve the engineering change applying Lean Office.

– San Mina, an Oil and Gas Company, Lean Office training and consulting, we reduce the total lead time from 10 to 5 days on the logistic chain including planning, purchasing, materials and engineering.

– DeAcero, wire division and steel. She participate on the DeAcero Production System, developing a continuous improvement system for logistic, purchasing, planning, shipping and production.

She has taught classes on Lean Manufacturing, Lean Logistics, Toyota Kata and Lean Office for different Universities as Tecnológico de Monterrey, UANL, UDEM, Universidad de Poza Rica, Universidad de Anáhuac, UPAEP.

Customers supported:

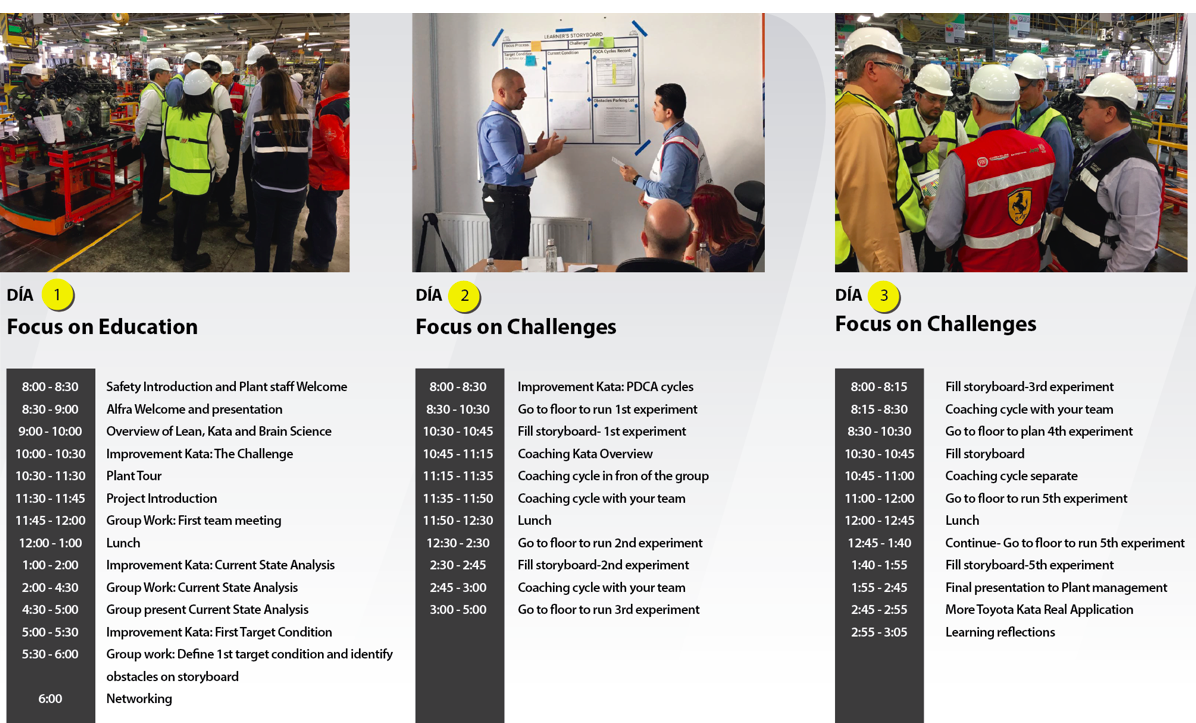

TRANSLATED TO 17 LANGUAGES

JEFFREY LIKER

Executive Advisor for ALFRA International two Best Seller with “The Toyota Way” & “Toyota Culture”

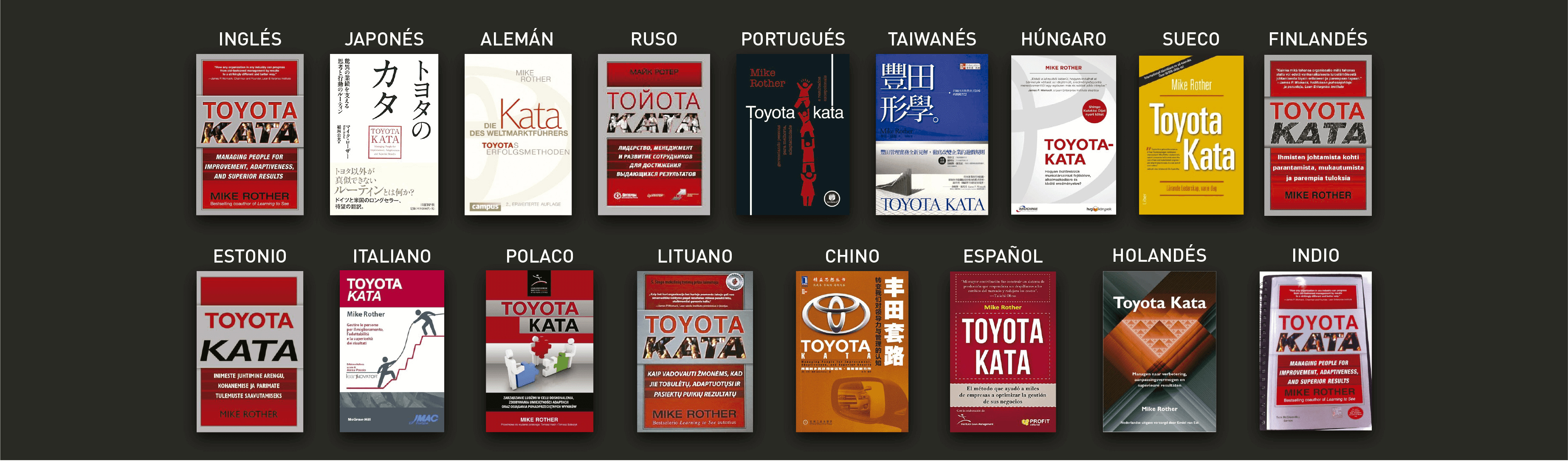

Dr. Jeffrey K. Liker is Professor of Industrial and Operations Engineering at the University of Michigan and President of Liker Lean Advisors. He is author of the international best-seller, The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer, 2004 (26 languages, over 950,000 copies sold), and has coauthored nine other books about Toyota including Toyota Culture, The Toyota Product Development System, The Toyota Way to Lean Leadership (2011) and Developing Lean Leaders at all Levels: A Practical Guide (2014). In 2016 he published The Toyota Way to Service Excellence and coauthored a lean transformation business novel called Trenches. His articles and books have won twelve Shingo Prizes for Research Excellence. In 2012 he was inducted into the Association of Manufacturing Excellence Hall of Fame and in 2016 inducted into the Shingo Academy.

SERVICES INCLUDED

- Manual

- Coffee break & Lunch

- Course Certificate.