Daily Management Development System

Establishing the Framework for Strategy Deployment (Hoshin Kanri)

14 Iunie, Timișoara

Go beyond the “typical” Lean Implementation

Most companies embarking on a lean journey soon become frustrated with improvement events and isolated projects that yield great short-term results but have no sustainability and no major innovation.

They are searching for something more: the culture that goes beyond “just managing” continuous improvement.

In this program we address the top factors that will take you “Beyond Lean” and out of the Improvement Trap.

Key benefits

- Learn by doing: Alignment of the organization’s goals and activities both vertically and horizontally”

- Creating, Implementing and Measuring key performance metrics and targets in the areas of Safety, Quality, Delivery and Cost (SQDC).

- Establish foundation for Strategy Deployment (Hoshin Kanri) cascade and driving people development and continuous improvement.

- Hands on development of selection of Hoshin “Breakthrough Focus Items”

- Learn how to set up the framework for daily management system to engage every level of management and team members towards driving business results

Hands On – Gemba Workshop at Host Company

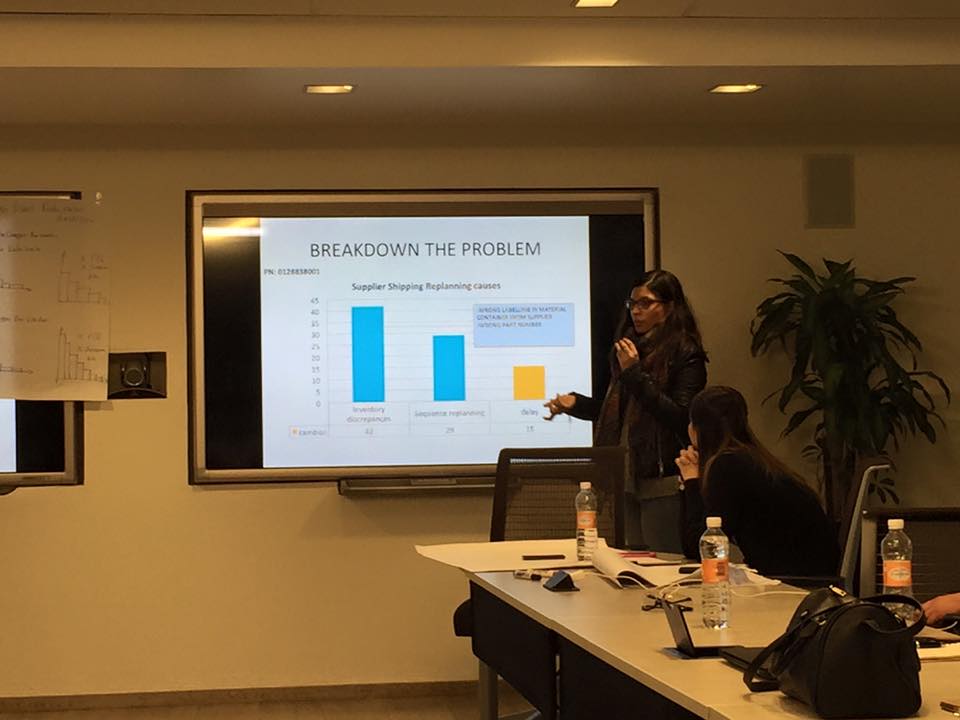

Real Problem Solving

Identify & solve the main opportunities aligned to the Hoshin (Company Strategy)

Group Discussion

Share experiences with managers from different industries and background

Shop Floor Exercises

The training is based in a real project environment in the host company

Training Lenght:

24 Hours (3 days)

Recommended Industries

Manufacturing Companies: Automotive, Electrical/Electronic, Pharmaceutical, Food & Beverages, Printing, Plastics, among others.

Who should attend?

CEO, President, Vice-Presidents, Executive Leaders, General Managers, Lean Leaders, and anyone facilitating change within your organization who understand the importance of going beyond tools to creating effective management systems and processes in order to set the basis for creating a sustainable lean culture.

PARTICIPANTS OPINION

TRAINING AGENDA: BODY OF KNOWLEDGE

Instructor

Jeff Strabala

Strategy & Operations Management Expert

Jeff worked for Toyota for over 21 years; his extensive experience is based in Operations Management in Toyota North America as Manager and internal consultant.

Jeff was member of the Leadership team for the launch of two “Greenfield” automotive plants and subsequent plant capacity expansions valued in $4.2 billion USD. During his tenure at Toyota, Jeff also spent 3 years of “internal consulting” with improvement projects at Toyota and Tier 1 suppliers plants adding value related to safety, visual and floor management, strategic planning, people development and financial controls.