Why Lean Manufacturing

A new approach for Production Management

The Lean management system (founded on the Toyota Production System) is a management philosophy which shortens the time between the customer order and the product shipment by eliminating all inefficiencies (sources of waste).

This it is ultimately reflected in terms of quality, delivery, cost and greater team morale, making a company capable to overcome bigger challenges and their competitors.

Workshop Highlights:

This 3 days workshop is a practical way to present the Lean principles concepts and its implementation in the shop floor (Gemba) from our host plant.

This program aims to develop participants, to really understand the lean principles (know why), and systems which support the behaviors of an operational excellence enterprise, the structure and deployment strategy for an initial phase of a lean transformation, which systems must be deployed and which triggers must be developed, explaining how to measure the deployment based on behaviors, which will deliver good process and results in soft and hard benefits.

Real Value Stream Mapping

A powerful method to analyze & Identify the main opportunities from a process

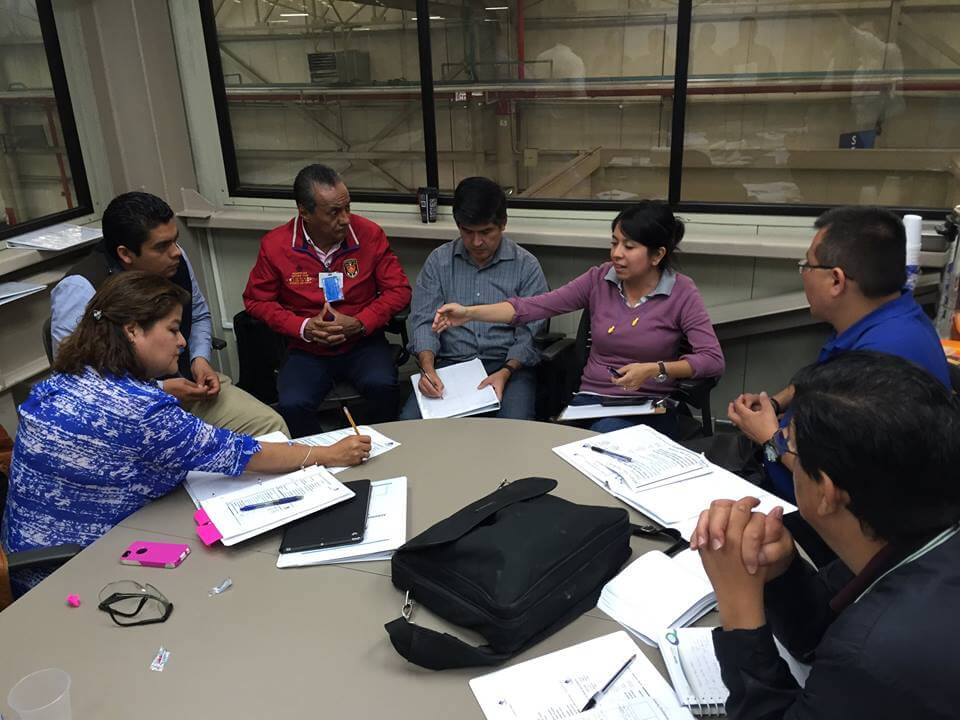

Shop floor (Gemba) Activities

Learn the Lean methods with practical team activities conducted on the shop floor.

Improvement Planning and Management

Learn how to plan and coordinate the improvement efforts in an effective way

Recommended Industries

Manufacturing Companies: Automotive, Electrical/Electronic, Pharmaceutical, Food & Beverages, Printing, Plastics, among others.

Who should attend?

Operations and Support departments Managers, Manufacturing, Quality & Engineering Middle levels, Lean Practitioners.

Training Lenght:

24 Hours (3 days)

Available seats

17 external participants per training

Why to participate?

- All exercises and applications are focused in real shop floor operations.

- Learn and receive direct feedback about Lean management from an experienced instructor

- Receive nurturing feedback from external participants from other industries

- Development of skills that can only be achieved by intensive practice and coaching.

Restrictions: External participants will sign a non-conflict of interest agreement, assuring they are not from a competitor company for the host company.

Training objectives on the plant

- Practical shop floor training in Lean principles and methods on the shop floor from our host plant with team based activities, participants get immerse into a kaizen teams.

- Analyze and develop a Value Stream Map from an entire production process (Selected by Host)

- Identify the main sources of waste in the entire process from a strategic point of view.

- Develop an action plan to establish a “Lean Production” System.

PARTICIPANTS OPINION

TRAINING AGENDA: BODY OF KNOWLEDGE

EVENIMENTE VIITOARE

Do you want to go further? we can answer any question

CONTACT US

Instructor

Edgar Cardenas Sanchez

International experience (Americas & Europe) in operational excellence deployment & training, for manufacturing & service environments, helping several customers to develop people & processes on their lean transformation journey , in several industry sectors including: Electronic Manufacturing, Food, Financial services, Plastics, Automotive, Logistics services, among others.