Gestione la Cultura y Mejora

Continua Lean de su Planta

EMDS

Enterprise Management

Development System

Gestione la Cultura y Mejora

Continua Lean de su Planta

EMDS

Enterprise Management

Development System

FECHA Y SEDE

Por Definir

Shop Floor Management / Administración de Operaciones de Planta

PROGRAMA

GALERÍA DE CURSOS ANTERIORES

EXPOSITORES

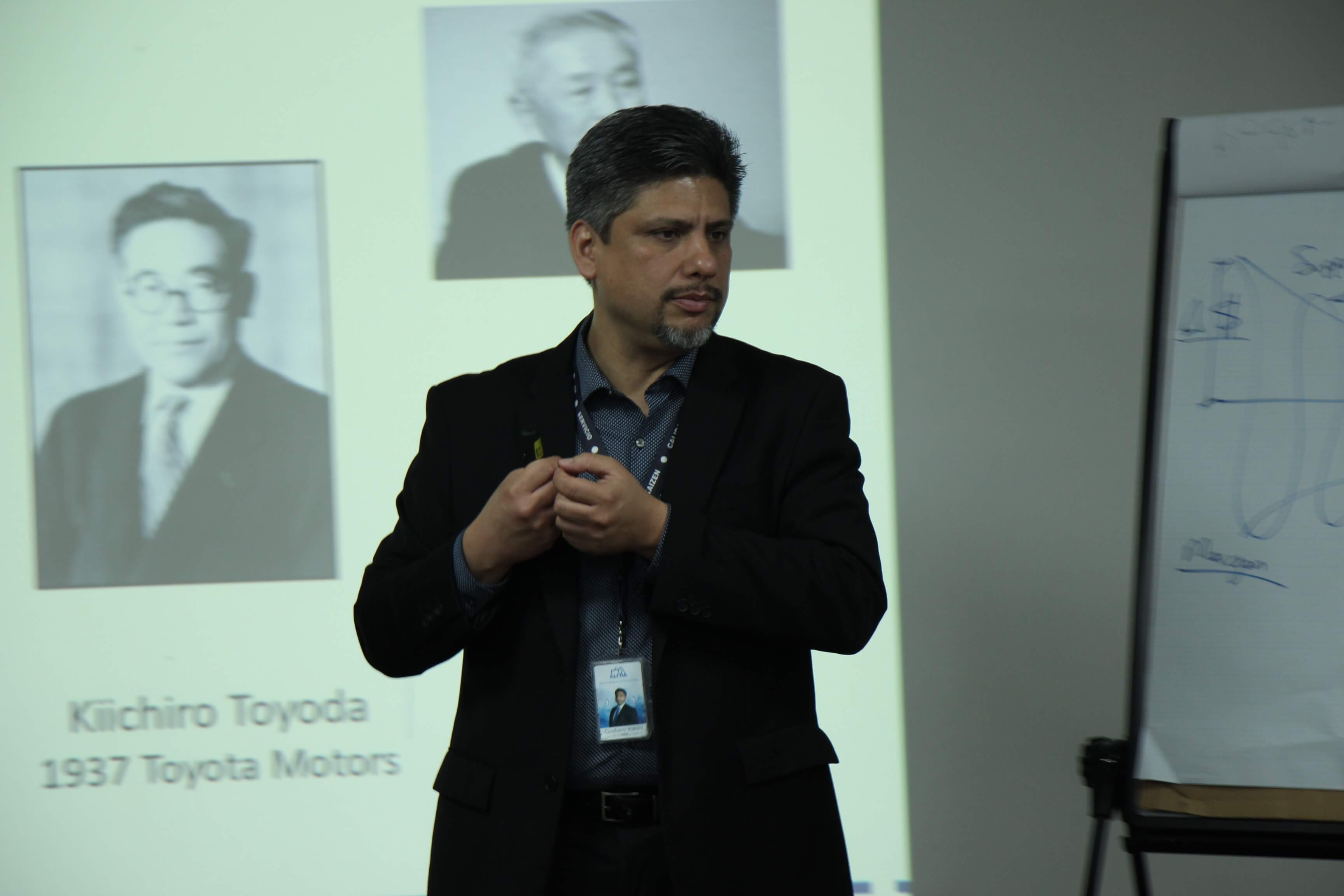

JEFF STRABALA

BSI, MOM Alfra Senior Director Consultant

At Toyota, Jeff was a member of the management and executive leadership teams at 5 North American Toyota Facilities and a Tier 1 Supplier. He has been instrumental in participating in and leading the launches of 2 “green field” automotive plants, and significant plant capacity expansions involving investment totaling over $4.2 billion USD. Experience within Toyota’s OMDD, North American internal consulting group. Jeff has 2,500+ flight hours as a US Navy helicopter pilot, and was an Operational Test Director for several US Navy Acquisition Programs valued over $300 million. Jeff Strabala, has experience on: Strategic and Hoshin Planning at Regional and Company levels, Production Planning and Control, Supply Chain and Logistics; Model Change Project Management (implemented ‘Gated Management” practice in N.A.); EMDS (Enterprise Management Development System – visual management – leading plant in N.A.); Material Flows including Kanban, Material Handling, Warehousing and Equipment; Financial Controls, Forecasting, Budgeting, Cost Accounting, Internal Controls; People Development, Evaluations, Training, Compensation and Incentives; Safety and Industrial Health Systems; Toyota Production System, Continuous Improvement and Lean Tools

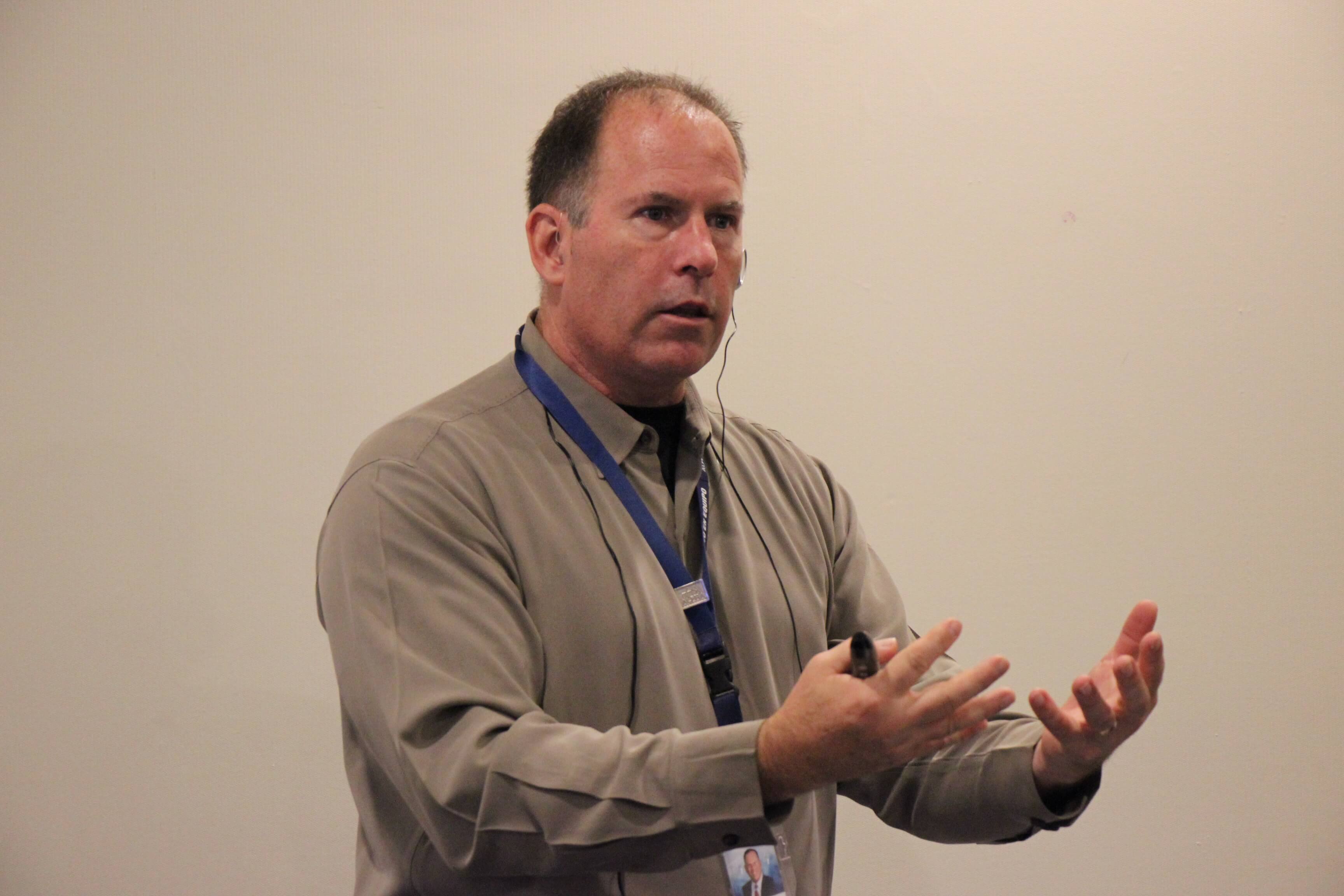

ALFONSO FELIX

SC, Especialidad Educación Cognoscitiva ITESO, D1 IPADE. Director General Bajío

Alfonso has accumulated +19 years of experience in the automotive industry serving in several functional areas and Top Management. He held several positions including Technology Information (serving Mexico, Brazil, Scotland and Japan), Materials Management (Mexico and USA), Operations and functioning as Plant Manager. Alfonso´s automotive experience includes 15 years working for American Axle and Manufacturing (AAM) and Nemak. Alfonso previously served as Technology Information Manager in a dairy company (Lechera Guadalajara) where he was part of a systems culture transformation for the whole company. Alfonso`s AAM`s plants won several Leadership and Productivity awards. Alfonso has been working with the Shingo Prize and other Organizations for the last 7 years being part of several conferences, serving as speaker, and acting as a Shingo Prize evaluator. He was part of 2010 Shingo Prize Japan study tour learning directly from several former Toyota Leaders. Alfonso´s experience includes Launching 6 brand new plants for AAM and Nemak serving in a different roles. He was part of the Lean Culture establishment for both companies new plants. He was part of the successful Production transition between USA and Mexico Plants for AAM that included 6 plants. He worked as a supplier for GM, FCA, Ford, VW, Audi, Nissan, BMW and other OEM`s. Bachelor of Computer Systems Engineering from ITESO in Guadalajara. Specialist in Education certified by ITESO. D1 Top Management Direction certified by IPADE. Japan Tour Lean Manufacturing and TPS studies with Utah University.

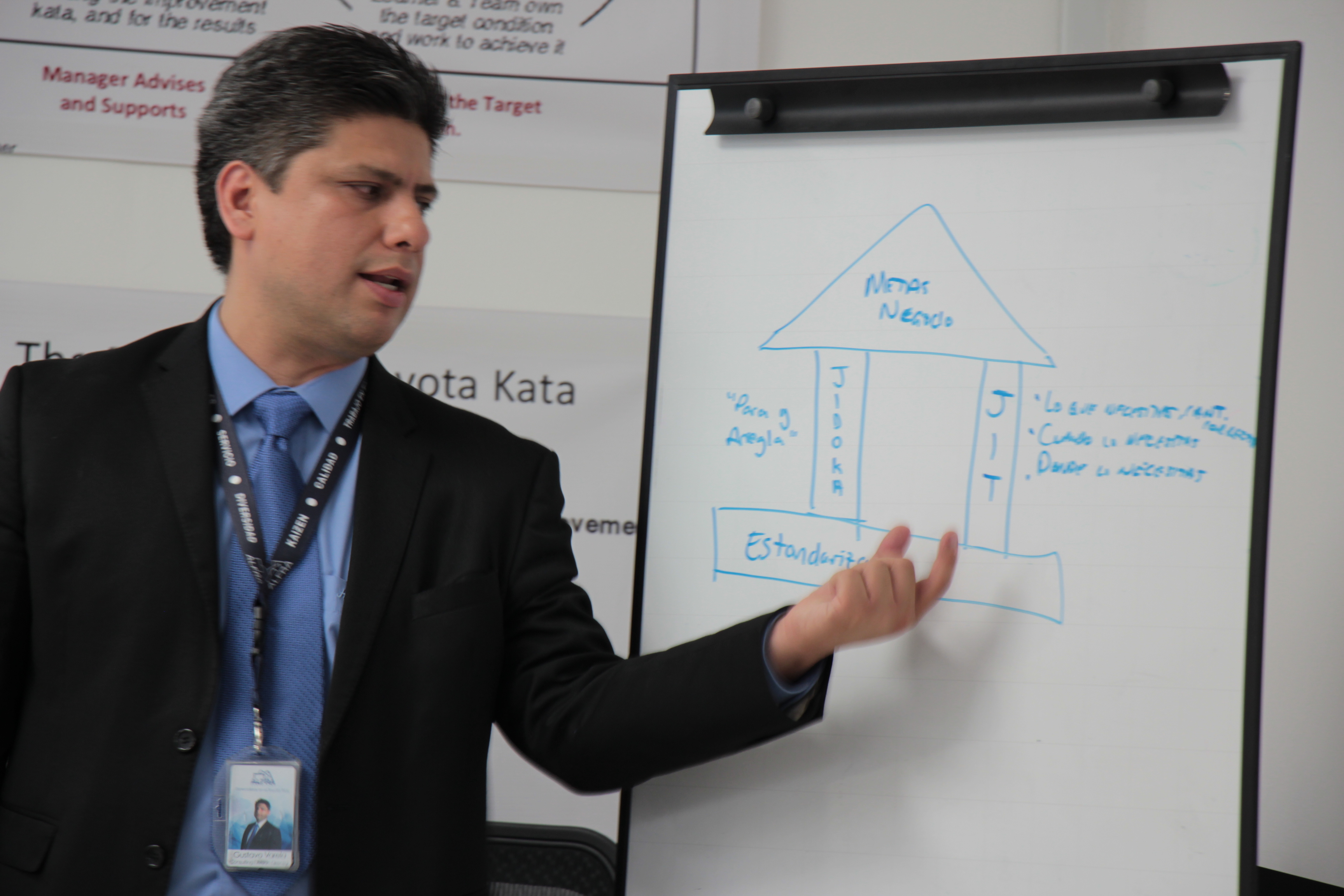

GUSTAVO VARELA

IMA, MBA, MBB. Director División de Consultoría

Based on his broad experience, Gustavo is expert applying a suitable approach for Continuous Improvement needed on the different organizations from a Business results optic, becoming an effective Coach for Top Management and support for The Toyota Way roles. Gustavo has learned The Toyota Way directly from its Author, Dr. Jeff Liker, and has applied it on Gemba as a Team with many Executives from Toyota specialized on General Management, TPM, Lean Mfg Tools, and Supply Chain. Gustavo has taught the Toyota Production System at all organizational levels and has applied over 50 companies of different sizes: Lean Leadership Systems (Hoshin Kanri, FMDS, and 8-Step Problem Solving), Toyota Kata for development, Supply Chain Management, TPM, Lean Manufacturing tools (5S’s, SW, SMED, Jidoka, Poka Yoke, Heijunka, JIT, etc.), and Lean Office approach. On Six Sigma, Gustavo as Master Black Belt has trained and certified +500 Black Belts, Green Belts, and Yellow Belts. Gustavo has +20 years of experience on Continuous Improvement, Manufacturing, Process Engineering and Quality in large companies: Motor Wheel (Automotive), Kodak, Philips, Daltile, American Standard. He has +12 years of experience as Vice/President Staff as Continuous Improvement Director for American Standard México and Master Black Belt Champion for Daltile México. He has deployed programs that have achieved +$110 Million USD in savings with +3,000 projects on all departments: R&D, Engineering, Manufacturing, Maintenance, Quality, Logistics, Supply Chain, Sales, Marketing, Finance, HR, Energy. Over his 22 years experience, Gustavo has been exposed to many different organizations applying suitable Lean approaches on a variety of systems with diversity on leadership styles.

SERVICIOS INCLUIDOS

- Agenda

- Horario (Iniciamos en tiempo)

- Coffee Break de Calidad

- Comida Incluida

- Manual a Color

- Certificado de entrenamiento

- Servicio de Traducción Simultánea (Costo Extra)

- Espacios Cómodos