TPS GEMBA

TRAINING AND MANAGEMENT

Date & Location

August 15th-17th 2018 Monterrey, Nuevo Leon

Host: DAIMLER Mercedes Benz

TPS GEMBA Training and Management

OBJECTIVES

1. Understand Lean or TPS firsthand from the Japanese perspective.

2. How Lean tools are applied correctly from Toyota’s perspective – a simple, effective way of scientific thinking.

3. Understand how to implement TPS through off-site Toyota operations.

4. Learn to see the waste and opportunities to improve from a leader’s perspective of operational excellence with a broad view on the floor of operations.

5. Improve your managerial leadership with your teams for effective results.

AIMED AT

- Directors of Operations

- Plant Managers

- Management

- Middle Controls in Development Plan

PROGRAM

| Day 1 | Day 2 | Day 3 |

|---|---|---|

|

|

|

| 1. 4S a) Topic (9:30-9:50) b) Gemba Practice (9:50-10:35) BREAK (10:35-10:50) c) Group discussion(10:50-11:10) d) Presentation (11:10-11:40) e) Comment & feedback (11:40-11:55)2. MUDA a) Topic (11:55-12:15) b) Gemba Practice: Gemba Walk to find muda (12:15-13:00) LUNCH: (13:00-13:30) c) Group discussion (13:30-13:50) d) Presentation (13:50-14:20) e) Comment & feedback (14:20-14:35)3. STANDARIZATION a) Topic (14:35-14:55) b) Gemba Practice: Pick up the process for standarization (14:55-15:10) c) Gemba practice: Video-film the same process for 2 operators (15:10-15:55) BREAK (15:55-16:10) d) Watch the video and discuss by the participants (16:10-16:30) e) Presentation (16:30-17:00) f) Comment & feedback (17:00-17:15) LEADER AND LEADERSHIP (17:15-18:00) |

4. TOTAL PARTICIPATION a) Topic (8:00-8:20) b) Gemba Practice: each group should pick up one process (8:20-9:05) c) Group discussion (9:05-9:25) d) Presentation (9:25-9:55) e) Comment & feedback (9:55-10:10) BREAK (10:10-10:25) MOTIVATION OF WORKERS (10:25-10:55)5. QUALITY CONTROL a) Topic (10:55-11:15) b) Gemba Practice (11:15-12:00) c) Group discussion (12:00-12:20) c) Presentation (12:20-12:50) e) Comment & feedback (12:50-13:05)6. GEMBAISM a) Topic (13:05-13:25) b) Gemba Practice: Gemba walk (13:25-14:10) LUNCH: 14:10-14:40 c) Group discussion (14:40-15:00) c) Presentation (15:00-15:30) d) Comment & feedback (15:30-15:45) BREAK (15:45-16:00)7. PULL AND PUSH SYSTEM a) Topic (16:00-16:20) b) Gemba practice:Gemba walk (16:20-17:05) |

7. PULL AND PUSH SYSTEM c) Group discussion (8:00-8:20) d) Presentation (8:20-8:50) e) Comment & feedback (8:50-9:05) BREAK: (9:05-9:20)8. VISUAL CONTROL a) Topic (9:20-9:40) b) Gemba Practice: Gemba walk (9:40-10:25) c) Group discussion (10:20-10:45) d) Presentation (10:45-11:15) e) Comment & feedback (11:15-11:30)9. LOT PRODUCTION / ONE PIECE FLOW a) Topic (11:30-11:50) b) Gemba Practice: Gemba walk (11:50-12:35) c) Group discussion (12:35-12:55) LUNCH: (12:55-13:25) d) Presentation (13:25-13:55) e) Comment & feedback (13:55-14:10)10. PROBLEM SOLVING a) Topic (14:10-14:30) b) Gemba Practice: find a problem (14:30-15:15) c) Group discussion (15:15-15:35) d) Presentation (15:35-16:05) e) Comment & feedback (16:05-16:20) CERTIFICATE AND PHOTO GROUP (16:20-16:50) |

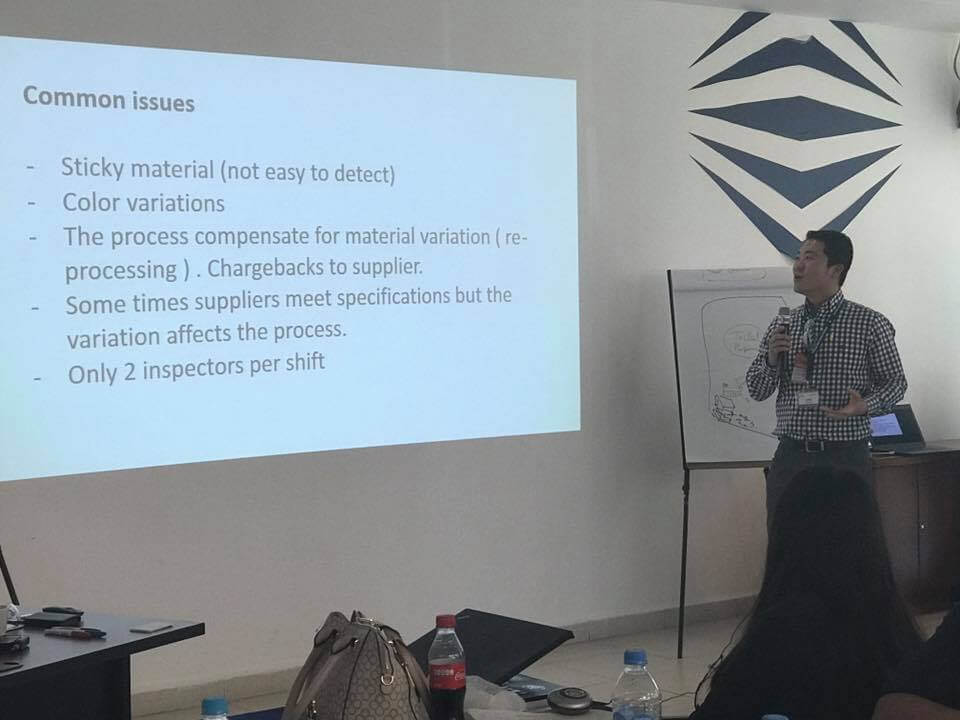

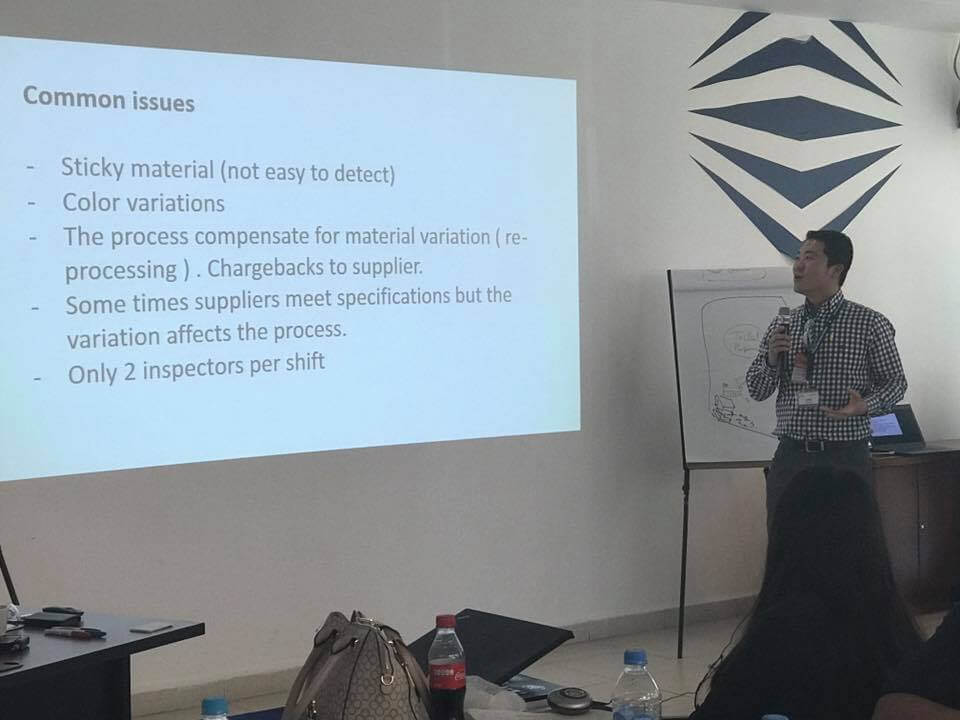

GALLERY OF PREVIOUS COURSES

INSTRUCTOR

RITSUO SHINGO

Executive ALFRA Consultant / Former Executive President of Toyota China and Hino Motors China / 44 Years Experience at Toyota

Siguiendo los pasos de su padre, que ha sido muy exitoso en la industria automotriz. Sr. Shingo comenzó su carrera con Toyota Motor Company en 1970, después de obtener el título de abogado en la Universidad de Waseda. Su padre, el Dr. Shigeo Shingo, se distinguió como uno de los principales expertos del mundo en la mejora de los procesos de fabricación y ha sido descrito como un “genio de la ingeniería”, que ayudó a crear y escribir sobre muchos aspectos de las prácticas en la revolución de la manufactura que comprenden el famoso Sistema de Producción Toyota. – Ha estado más de 13 años en varios Roles de Toyota ́s Legal. – Gastó 2 años en Toyota Motor Kentucky, luego regresó al Departamento de Compras en Japón – Ha estado trabajando para Toyota Motor UK después regresó a China eventualmente convirtiéndose en presidente de Toyota China en 1998. – Ingresando en Hino Motors China en el 2004 y fue nombrado presidente de la misma en la junta en el 2007. – En 2007, recién había establecido el Joint Venture entre Hino Motors y Guang-Qi Motors y se convirtió en el primer presidente de la Joint Venture. – Octubre 2012, Presidente “Institute of Management Improvement”.

SERVICES INCLUDED

The Training Certificate will be finalized 6 months after attending the course and presenting the implementation and results obtained.

- Coffee Break & Lunch

- Manual

- Certificate of training

- Simultaneous Translation Service ($130.00 MN + Tax / per day)