LEAN SYSTEMS FOR LEADERSHIP ACCOUNTABILITIES

LEAN SYSTEMS FOR LEADERSHIP ACCOUNTABILITIES

FECHA & SEDE

FECHA Y SEDE

por definir

Sistema de Mejora de operaciones y alcance de objetivos mediante Coaching de Gerencias y Mandos Medios.

DESCRIPCIÓN:

El Líder: pieza clave en los resultados y sustentabilidad de una organización. Los retos más comunes que presentan los líderes son precisamente en los roles principales que requieren llevar a cabo cada año y cada día: alineación dinámica de toda la organización, administración efectiva de las distintas áreas del negocio a todos los niveles y el desarrollo continuo tanto de los procesos como del personal, todo, para lograr los objetivos a corto plazo y la sustentabilidad de largo plazo.

Los Sistemas Lean que todo Líder en Toyota aplica como sustento y guía en su propio camino hacia el éxito en sus roles principales son:

- Hoshin Kanri – Planeación Estratégica Dinámica.

- EMDS: Enterprise Management Development System. Para la efectividad diaria / semanal / mensual / anual de toda la organización.

- Toyota Kata. Ampliar el conocimiento y aprendizaje organizacional de los procesos hacia mejores resultados.

Entrenamiento Toyota Kata Infield WESTROCK BrasilEntrenamiento Toyota Kata Infield WESTROCK Brasil

Posted by ALFRA Lean Advisors on Wednesday, March 29, 2017

OBJETIVOS

Entender las características de los Sistemas Lean para el Liderazgo y como se interrelacionan para facilitar la labor inter-conectada de todos los Líderes de cualquier organización.

OBJETIVOS

Comprender, bajo un método teórico y práctico, cada uno de los sistemas Lean y como se pueden aplicar a cada organización.

OBJETIVOS

Conocer los Sistemas Lean para el Liderazgo aplicados en una Empresa y compartir los retos y beneficios que conlleva su implementación y operación diaria.

DIRIGIDO A:

CEO, Presidente, Vicepresidentes, Líderes Ejecutivos, Directores Generales, Líderes Lean, y cualquier persona que facilite el cambio dentro de su organización que entienden la importancia de ir más allá de las herramientas para la creación de sistemas y procesos de gestión eficaces con el fin de sentar las bases para la creación de una sostenible cultura lean.

OBJETIVOS

- Entender las características de los Sistemas Lean para el Liderazgo y como se interrelacionan para facilitar la labor inter-conectada de todos los Líderes de cualquier organización.

- Comprender, bajo un método teórico y práctico, cada uno de los sistemas Lean y como se pueden aplicar a cada organización.

- Conocer los Sistemas Lean para el Liderazgo aplicados en una Empresa y compartir los retos y beneficios que conlleva su implementación y operación diaria.

DIRIGIDO A

CEO, Presidente, Vicepresidentes, Líderes Ejecutivos, Directores Generales, Líderes Lean, y cualquier persona que facilite el cambio dentro de su organización que entienden la importancia de ir más allá de las herramientas para la creación de sistemas y procesos de gestión eficaces con el fin de sentar las bases para la creación de una sostenible cultura lean.

PROGRAMA

| 26 & 27: HOSHIN KANRI |

|---|

|

Seminario de MejoraI. BIENVENIDA Y RECORRIDO DE PLANTA II. Hoshin Kanri – Planificación estratégica dinámica. Introducción.

Lean Leadership System: proceso de implementación de estrategias en 6 pasos. Evaluación – Determinar “Estado actual – Estado futuro y lagunas a abordar”

Conexión al sistema Lean Management y Enterprise Management Sistema de desarrollo (EMDS)

Ejercicio: crear el plan estratégico: priorizar y seleccionar “elementos clave de lean”

III. EMDS: Sistema de desarrollo de gestión empresarial. Para la efectividad diaria / semanal / mensual / anual de toda la organización. |

|

27 & 28: EMDS

|

|

Elementos Generales de EMDS

Pizarrones de Gestión de la Operación

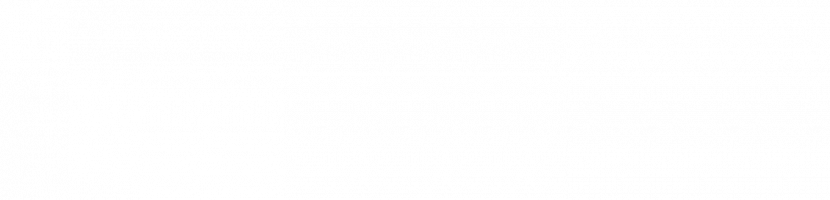

Trabajo Estandarizado de Líderes

Juntas de Rendición de Cuentas (Tier Meetings)

Disciplina

IV. Toyota Kata. Ampliar el conocimiento y aprendizaje organizacional de los procesos hacia mejores resultados.

|

|

29 & 30: TOYOTA KATA

|

|

ENFOQUE EN LA EDUCACIÓN

ENFOQUE EN LOS DESAFÍOS

|

| 26 & 27: HOSHIN KANRI | 27 & 28: EMDS | 29 & 30: TOYOTA KATA |

|

|

|

Seminario de MejoraI. BIENVENIDA Y RECORRIDO DE PLANTA II. Hoshin Kanri – Planificación estratégica dinámica. Introducción.

Lean Leadership System: proceso de implementación de estrategias en 6 pasos. Evaluación – Determinar “Estado actual – Estado futuro y lagunas a abordar”

Conexión al sistema Lean Management y Enterprise Management Sistema de desarrollo (EMDS)

Ejercicio: crear el plan estratégico: priorizar y seleccionar “elementos clave de lean”

III. EMDS: Sistema de desarrollo de gestión empresarial. Para la efectividad diaria / semanal / mensual / anual de toda la organización. |

Elementos Generales de EMDS

Pizarrones de Gestión de la Operación

Trabajo Estandarizado de Líderes

Juntas de Rendición de Cuentas (Tier Meetings)

Disciplina

IV. Toyota Kata. Ampliar el conocimiento y aprendizaje organizacional de los procesos hacia mejores resultados.

|

ENFOQUE EN LA EDUCACIÓN

ENFOQUE EN LOS DESAFÍOS

|

EXPOSITORES

Francisco Ocejo is leading Alfra Lean Advisors a Consulting firm with over 1,500 customers companies from 14 countries around the world. ALFRA Support companies Lean transformation from Strategic Planning, SCM, OPS, HR, Sales, Finance.

He has been learning, applying, and teaching the Toyota Production System in Canada, USA, Mexico, Latin America & Europe. He has taught and applied Lean from the senior management level to the operational levels closest to Gemba fro over 150 companies from international corporations, to mid-size and small family businesses from diferent industry sectors such as: Service, Logistics, Aerospace, Automotive, Electronic, Bank, Ceramic, Education, Defense Electronic, Food & Beverage, Gas & Oil, Electric Manufacturing, and several manufacturing sectors.

Francisco is a Toyota Kata Ambassador and Pioneer to spread the Toyota Kata in Mexico, he has been applying TK with his colleague Dr. Jeff Liker ( author of the best seller the toyota Way) and many other Coaches in companies with the hieghest TPS people development.

For over 5 years he has been constantly trained by the Best Seller “Toyota Way (800 hrs),” the Ex President of JV Toyota China Mr Shingo (360 hrs), and various Toyota top Management ( + 1000 hrs).

His best expertise is in: Coaching Toyota Kata, Lean Manufacturing ,Lean Office, Lean Culture and Business Transformation.

He is an Industrial and Systems Engineering at the Monterrey Technical Institute. He has taught classes for students in over 15 Universities, lecturing in various Congresses in Mexico. Certified as Black Belt Six Sigma at Institution of Industrial Engineers, and the Theory of Constraints and Thinking Process at the EGADE of the Monterrey Technical Institute.

Francisco is a former Celestica leader & manager of the Lean Culture Transformation, with BlackBerry (RIM), Palm, HTC as Principals customers, with sales of over 1 billion dollars. This transformation involved over 5,000 people.

Based on his broad experience, Gustavo is expert applying a suitable approach for Continuous Improvement needed on the different organizations from a Business results optic, becoming an effective Coach for Top Management and support for The Toyota Way roles. Gustavo has learned The Toyota Way directly from its Author, Dr. Jeff Liker, and has applied it on Gemba as a Team with many Executives from Toyota specialized on General Management, TPM, Lean Mfg Tools, and Supply Chain. Gustavo has taught the Toyota Production System at all organizational levels and has applied over 50 companies of different sizes: Lean Leadership Systems (Hoshin Kanri, FMDS, and 8-Step Problem Solving), Toyota Kata for development, Supply Chain Management, TPM, Lean Manufacturing tools (5S’s, SW, SMED, Jidoka, Poka Yoke, Heijunka, JIT, etc.), and Lean Office approach. On Six Sigma, Gustavo as Master Black Belt has trained and certified +500 Black Belts, Green Belts, and Yellow Belts. Gustavo has +20 years of experience on Continuous Improvement, Manufacturing, Process Engineering and Quality in large companies: Motor Wheel (Automotive), Kodak, Philips, Daltile, American Standard. He has +12 years of experience as Vice/President Staff as Continuous Improvement Director for American Standard México and Master Black Belt Champion for Daltile México. He has deployed programs that have achieved +$110 Million USD in savings with +3,000 projects on all departments: R&D, Engineering, Manufacturing, Maintenance, Quality, Logistics, Supply Chain, Sales, Marketing, Finance, HR, Energy. Over his 22 years experience, Gustavo has been exposed to many different organizations applying suitable Lean approaches on a variety of systems with diversity on leadership styles.

FRANCISCO OCEJO

Liker Lean Advisors Vice President

Toyota Kata Ambassador

Former VP IISE

Former Lean Manager at Celestica

Education

B.S. Industrial Engineering at Tec de Monterrey

Several Lean Certifications for international Institutes

Francisco Ocejo is leading Alfra Lean Advisors a Consulting firm with over 1,500 customers companies from 14 countries around the world. ALFRA Support companies Lean transformation from Strategic Planning, SCM, OPS, HR, Sales, Finance.

He has been learning, applying, and teaching the Toyota Production System in Canada, USA, Mexico, Latin America & Europe. He has taught and applied Lean from the senior management level to the operational levels closest to Gemba fro over 150 companies from international corporations, to mid-size and small family businesses from diferent industry sectors such as: Service, Logistics, Aerospace, Automotive, Electronic, Bank, Ceramic, Education, Defense Electronic, Food & Beverage, Gas & Oil, Electric Manufacturing, and several manufacturing sectors.

Francisco is a Toyota Kata Ambassador and Pioneer to spread the Toyota Kata in Mexico, he has been applying TK with his colleague Dr. Jeff Liker ( author of the best seller the toyota Way) and many other Coaches in companies with the hieghest TPS people development.

For over 5 years he has been constantly trained by the Best Seller “Toyota Way (800 hrs),” the Ex President of JV Toyota China Mr Shingo (360 hrs), and various Toyota top Management ( + 1000 hrs).

His best expertise is in: Coaching Toyota Kata, Lean Manufacturing ,Lean Office, Lean Culture and Business Transformation.

He is an Industrial and Systems Engineering at the Monterrey Technical Institute. He has taught classes for students in over 15 Universities, lecturing in various Congresses in Mexico. Certified as Black Belt Six Sigma at Institution of Industrial Engineers, and the Theory of Constraints and Thinking Process at the EGADE of the Monterrey Technical Institute.

Francisco is a former Celestica leader & manager of the Lean Culture Transformation, with BlackBerry (RIM), Palm, HTC as Principals customers, with sales of over 1 billion dollars. This transformation involved over 5,000 people.

GUSTAVO VARELA

IMA, MBA, MBB. Director División de Consultoría

Based on his broad experience, Gustavo is expert applying a suitable approach for Continuous Improvement needed on the different organizations from a Business results optic, becoming an effective Coach for Top Management and support for The Toyota Way roles.

Gustavo has learned The Toyota Way directly from its Author, Dr. Jeff Liker, and has applied it on Gemba as a Team with many Executives from Toyota specialized on General Management, TPM, Lean Mfg Tools, and Supply Chain. Gustavo has taught the Toyota Production System at all organizational levels and has applied over 50 companies of different sizes: Lean Leadership Systems (Hoshin Kanri, FMDS, and 8-Step Problem Solving), Toyota Kata for development, Supply Chain Management, TPM, Lean Manufacturing tools (5S’s, SW, SMED, Jidoka, Poka Yoke, Heijunka, JIT, etc.), and Lean Office approach. On Six Sigma, Gustavo as Master Black Belt has trained and certified +500 Black Belts, Green Belts, and Yellow Belts.

Gustavo has +20 years of experience on Continuous Improvement, Manufacturing, Process Engineering and Quality in large companies: Motor Wheel (Automotive), Kodak, Philips, Daltile, American Standard. He has +12 years of experience as Vice/President Staff as Continuous Improvement Director for American Standard México and Master Black Belt Champion for Daltile México. He has deployed programs that have achieved +$110 Million USD in savings with +3,000 projects on all departments: R&D, Engineering, Manufacturing, Maintenance, Quality, Logistics, Supply Chain, Sales, Marketing, Finance, HR, Energy. Over his 22 years experience, Gustavo has been exposed to many different organizations applying suitable Lean approaches on a variety of systems with diversity on leadership styles.

SERVICIOS INCLUIDOS

Manual

Coffee break & Lunch

Certificado del curso.

SERVICIOS INCLUIDOS

- Manual digital

- Coffee Break y comida.

- Certificado de curso