SISTEMAS LEAN PARA LIDERAZGO: Hoshin Kanri

El Líder: pieza clave en los resultados y sustentabilidad de una organización. Los retos más comunes que presentan los líderes son precisamente en los roles principales que requieren llevar a cabo cada año y cada día: alineación dinámica de toda la organización, administración efectiva de las distintas áreas del negocio a todos los niveles y el desarrollo continuo tanto de los procesos como del personal, todo, para lograr los objetivos a corto plazo y la sustentabilidad de largo plazo.

Uno de los Sistemas Lean que todo Líder en Toyota aplica como sustento y guía en su propio camino hacia el éxito en sus roles principales son:

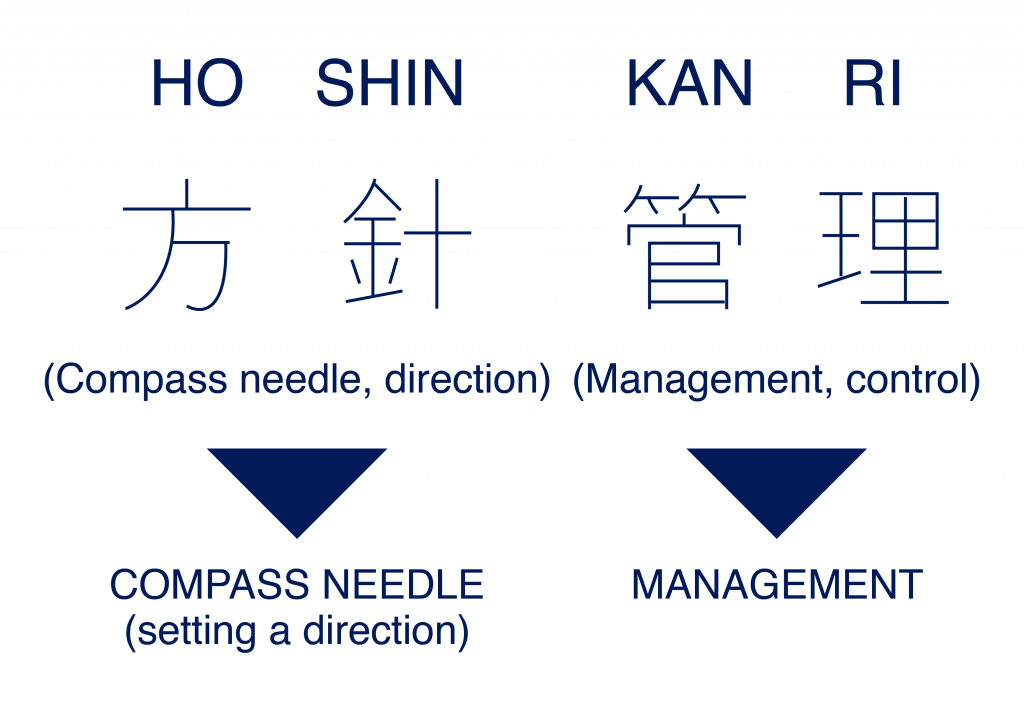

- Hoshin Kanri – Planeación Estratégica Dinámica.

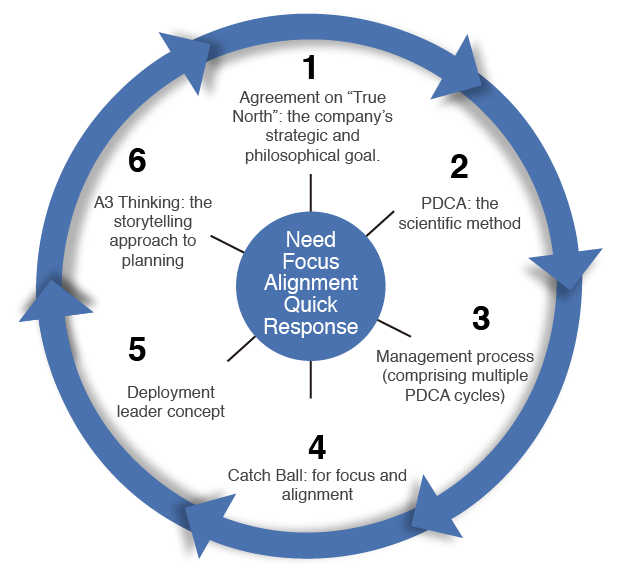

HOSHIN KANRI PROCESS

OBJETIVOS

1. Entender las características de los Sistemas Lean para el Liderazgo y como se interrelacionan para facilitar la labor inter-conectada de todos los Líderes de cualquier organización.

2. Comprender, bajo un método teórico y práctico, cada uno de los sistemas Lean y como se pueden aplicar a cada organización.

3. Conocer los Sistemas Lean para el Liderazgo aplicados en una Empresa y compartir los retos y beneficios que conlleva su implementación y operación diaria.

DIRIGIDO A

CEO, Presidente, Vicepresidentes, Líderes Ejecutivos, Directores Generales, Líderes Lean, y cualquier persona que facilite el cambio dentro de su organización que entienden la importancia de ir más allá de las herramientas para la creación de sistemas y procesos de gestión eficaces con el fin de sentar las bases para la creación de una sostenible cultura lean.

PROGRAMA

| Día 1 | Día 2 |

|---|---|

| 2:00 pm a 6:00pm

Sistema de Liderazgo Lean: Proceso de Implementación de la Estrategia

|

8:00 am a 12:00pm

Ejercicio SWOT de cinco años y KPI de 5 años

1:00pm – 5:00pm Cree el plan: conexión con el sistema de gestión Lean y el sistema de desarrollo de gestión empresarial (EMDS)

|

EXPOSITORES

GUSTAVO VARELA

Former American Standard Continuous Improvement Director

Former Daltile Master Black Belt

22 years experience. +17 years as Global Continuous Improvement Leader

Based on his broad experience, Gustavo is expert applying a suitable approach for Continuous Improvement needed on the different organizations from a Business results optic, becoming an effective Coach for Top Management and support for The Toyota Way roles.

Gustavo has learned The Toyota Way directly from its Author, Dr. Jeff Liker, and has applied it on Gemba as a Team with many Executives from Toyota specialized on General Management, TPM, Lean Mfg Tools, and Supply Chain. Gustavo has taught the Toyota Production System at all organizational levels and has applied over 50 companies of different sizes: Lean Leadership Systems (Hoshin Kanri, FMDS, and 8-Step Problem Solving), Toyota Kata for development, Supply Chain Management, TPM, Lean Manufacturing tools (5S’s, SW, SMED, Jidoka, Poka Yoke, Heijunka, JIT, etc.), and Lean Office approach. On Six Sigma, Gustavo as Master Black Belt has trained and certified +500 Black Belts, Green Belts, and Yellow Belts.

Gustavo has +20 years of experience on Continuous Improvement, Manufacturing, Process Engineering and Quality in large companies: Motor Wheel (Automotive), Kodak, Philips, Daltile, American Standard. He has +12 years of experience as Vice/President Staff as Continuous Improvement Director for American Standard México and Master Black Belt Champion for Daltile México. He has deployed programs that have achieved +$110 Million USD in savings with +3,000 projects on all departments: R&D, Engineering, Manufacturing, Maintenance, Quality, Logistics, Supply Chain, Sales, Marketing, Finance, HR, Energy. Over his 22 years experience, Gustavo has been exposed to many different organizations applying suitable Lean approaches on a variety of systems with diversity on leadership styles.

RODOLFO BOJORQUEZ

Professional Summary

Karcher Mexico Materials Manager

Amphenol Cemmex Logistics Manager

JCI Components Plant Planning and Production

Controls Manager

Rodolfo is an Advisor for Lean Operations with experience in global companies within Strategic Planning, Lean Operations, Supply Chain, HR, Sales &Finance.

He has been learning and developed on improve the all Supply Chain in Industrial environment. Using tools of Toyota Production System and Six Sigma Rodolfo has impacted positively the Supply reducing lead times, Inventories, improving processes, etc. Creating more lean operations and supporting people.

As expatriate on USA for JCI, he was able to support implementation of ERP SAP to improve process and quality of supply chain on 3 plants.

Rodolfo is a change agent enrolled with the high demand of the automotive industry, focused on results, but not leaving human side, values and caring for business interests

For over 15 years he has been constantly trained and deploying Improvement Projects to maximize as much resources possible to make thing better and easier, Rodolfo has been trained in the Toyota Way Culture, connecting the Lean Supply for the customers.

Rodolfo can help your team to accomplish their goals, to make things happen, meaning Business Transformation on Lean Supply to Lean Culture