SISTEMAS LEAN PARA LIDERAZGO: Hoshin Kanri

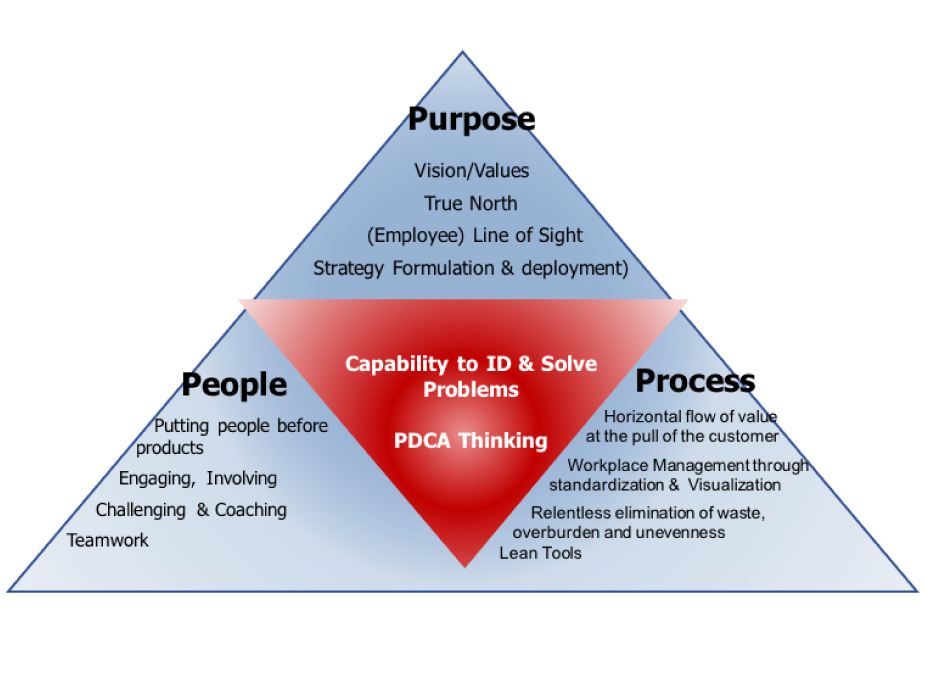

Los retos más comunes que presentan los líderes son precisamente en los roles principales que requieren llevar a cabo cada año y cada día: alineación dinámica de toda la organización, administración efectiva de las distintas áreas del negocio a todos los niveles y el desarrollo continuo tanto de los procesos como del personal, todo, para lograr los objetivos a corto plazo y la sustentabilidad de largo plazo.

Uno de los Sistemas Lean que todo Líder en Toyota aplica como sustento y guía en su propio camino hacia el éxito en sus roles principales son:

- Planeación Estratégica Dinámica.

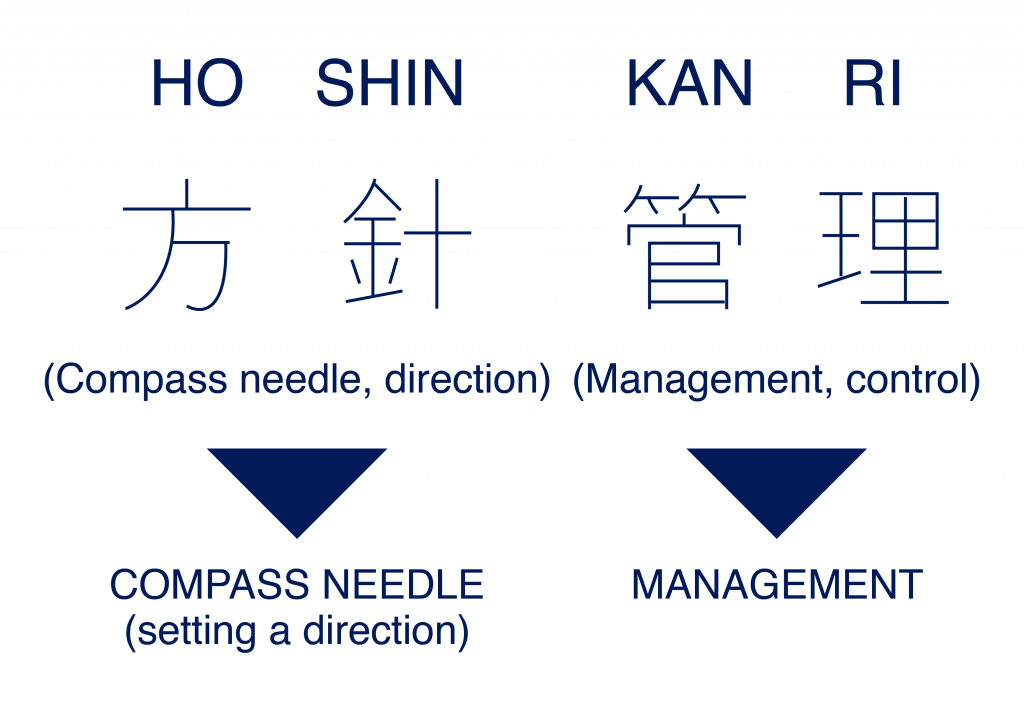

Hoshin Kanri

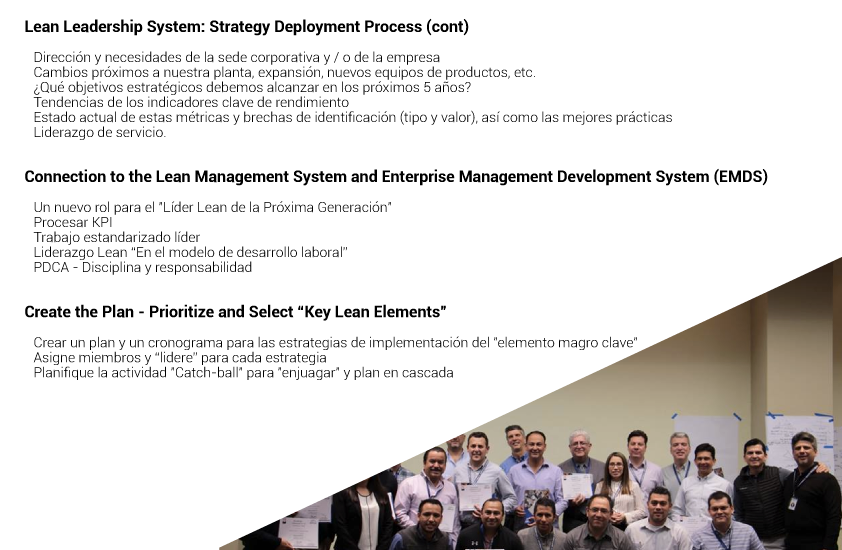

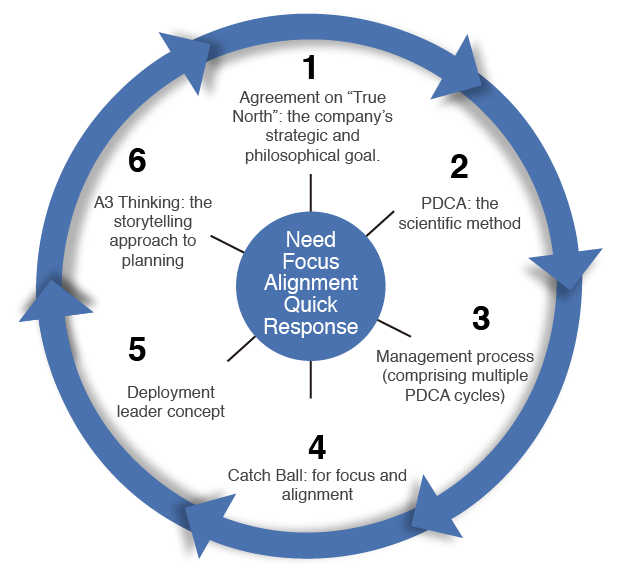

Esta será una sesión “en vivo” para que los equipos de liderazgo participen en una sesión de Planificación Estratégica para su organización. Este proceso de planificación estratégica está diseñado para ir mucho más allá del típico proceso de “Gestión por objetivos” o MBO utilizado por muchas organizaciones. El SP es un proceso de “arriba hacia abajo” y “de abajo hacia arriba” que aprovecha el poder de toda la organización, no solo de unos pocos líderes. Obtendrá a todos en la organización en la misma página a través de su “Norte Verdadero” y a través de un proceso de atrapar la pelota que atraviesa la organización tanto vertical como horizontalmente. La alineación resultante hará que todos vayan en la misma dirección, enfocándose en los principales problemas “pocos vitales” en la organización. El proceso luego aprovechará la creatividad de los equipos para abordar estos problemas al enfocarse no solo en los resultados sino también en el “proceso”, que no solo ayudará a lograr los resultados, sino que permitirá a la organización estandarizarlos, mantenerlos y compartirlos por mucho tiempo. término prosperidad.

HOSHIN KANRI PROCESS

OBJETIVOS

1. Entender las características de los Sistemas Lean para el Liderazgo y como se interrelacionan para facilitar la labor inter-conectada de todos los Líderes de cualquier organización.

2. Comprender, bajo un método teórico y práctico, cada uno de los sistemas Lean y como se pueden aplicar a cada organización.

3. Conocer los Sistemas Lean para el Liderazgo aplicados en una Empresa y compartir los retos y beneficios que conlleva su implementación y operación diaria.

DIRIGIDO A

CEO, presidente, vicepresidentes, líderes ejecutivos, gerentes generales, líderes magras y cualquier persona que facilite el cambio dentro de su organización que entienda la importancia de ir más allá de las herramientas para crear sistemas y procesos de gestión efectivos con el fin de establecer las bases para crear una base sostenible cultura magra

PROGRAMA

EXPOSITORES

GUSTAVO VARELA

ALFRA Consulting Division Director

Former American Standard Continuous Improvement Director

Former Daltile Master Black Belt

25 years experience. +20 years as Global Continuous Improvement Leader

Education

Bachelor of Mechanics and Administration

MBA from UANL

Master Black Belt certified by ITESM.

Gustavo is supporting global organizations in their different facilities around Americas, implementing Top management System and deploy to next levels eliminating cost, improving capacity, and achieving main goals for each of their plants.

Into Gustavo Experience directly in action are companies from different industry sectors such as: Automotive, Aerospace, Steel, Electronic, Food, Ceramic, Services, Logistics, Oil, Electrical. He is always working with plant managers with different experiences an challenges.

Gustavo has learned The Toyota Way directly from its Author, Dr. Jeff Liker, and has applied it on Gemba as a Team with many Executives from Toyota specialized on General Management, TPM, Lean Mfg Tools, and Supply Chain.

Gustavo has taught the Toyota Production System at all organizational levels and has applied over 50 companies of different sizes: Lean Leadership Systems (Hoshin Kanri, FMDS, and 8-Step Problem Solving), Toyota Kata for development, Supply Chain Management, TPM, Lean Manufacturing tools (5S’s, SW, SMED, Jidoka, Poka Yoke, Heijunka, JIT, etc.), and Lean Office approach. On Six Sigma, Gustavo as Master Black Belt has trained and certified +500 Black Belts, Green Belts, and Yellow Belts.

He has +12 years of experience as Vice/President Staff as Continuous Improvement Director for American Standard México and Master Black Belt Champion for Daltile México. He has deployed programs that have achieved +$110 Million USD in savings with +3,000 projects on all departments: R&D, Engineering, Manufacturing, Maintenance, Quality, Logistics, Supply Chain, Sales, Marketing, Finance, HR, Energy. Over his 22 years experience, Gustavo has been exposed to many different organizations applying suitable Lean approaches on a variety of systems with diversity on leadership styles.

ANOTNIO PÉREZ

Professional Summary

- Former Plant Director at Fiat-Chrysler in charge of 3 plants.

- Former Plant manager for Magneti Marelli and Aptiv

- +20 years developing teams to superior performance as senior management Culture as Leader

Education:

- Master on Industrial engineer

- Electronic and Communications Engineer

Trajectory Highlights:

Antonio has wide experience at Director level, with extensive experience leading world class organizations as Fiat-Chrysler, Aptiv or Marelli Suspension, where he managed to develop a lean culture in plants with +1400 employees.

In his +25 years as leader, Antonio has growth coaching skills to develop management and front line people to deliver highest performance through daily routines and practices (leader standard work), with special attention on always to challenge people, promote training and foster the right behaviors.

When developing teams the main focus has been to transmit the Lean management principles that promotes Safety, Quality, Cost, Delivery and Moral.

His background enables him to implement systems to improve competitiveness, health and make companies more profitable, with responsibilities in Mexico, USA, Brazil and Italy.

Some of Antonio’s achievements as Director:

- Zero accidents since plant start up until end of tenure (more than 2 million hours) achieving National Safety Council Award from 2014, 2015, 2016 and 2017.

- Build an excellent relationship with workers union and engage them on Lean Manufacturing activities, having an average of 20 ideas by employee (Union and non-Union) becoming benchmark for Fiat-Chrysler in America.

- Develop autonomous teams using the Lean Manufacturing systems to improve KPI’s on all areas with 5 million dollars saving from Budget.

- Scrap reduction in +50% implementing kaizen activities at all levels of the company.

MICHAEL HOSEUS

ALFRA Toyota Team Director Former Executive Plant Manager of Toyota Kentucky

- Best Seller of the Toyota Culture

- Associate Executive Advisor for ALFRA Lean Advisors

- Former Toyota Assistant General Manager

- Former Assistant General Manager and Human Resources

- Executive Director CQPO

Mike is Executive Director for the Center for Quality People & Organizations (CQPO). Mike Hoseus brings both manufacturing operations and specialization in Human Resource experience to CQPO. CQPO is an organization developed in 1999 as a vision of Toyota Motor Manufacturing to share Lean Quality philosophy and human resource practices with education, business, and community organizations. CQPO current projects with Toyota include New Hire selection and training process, Team Leader and Group Leader post promotion training, Quality Circle Leader and Manager training, and Global Problem Solving for all levels. Mike is an adjunct professor with the University of Kentucky’s Lean Manufacturing Program. Mike is co author with Dr. Jeffery Liker (Author of the Toyota Way) of Toyota Culture. Mike is an adjunct professor with the University of Kentucky’s Center for Manufacturing and a member of the faculty of Lean Enterprise Institute. Mike is also president of Lean Culture Enterprises. Prior to CQPO, Mike was a corporate leader for 13 years at Toyota Motor Manufacturing’s Georgetown, Kentucky, plant both in Human Resources and Manufacturing. As Assistant General Manager in Human Resources, his responsibilities included personnel, safety, HR development, employee relations, benefits, training, and manufacturing/human resource teams for a plant of 8000 team members. His major initiative was development of the enhanced relationship between Human Resource and Manufacturing Mike’s operational responsibilities in manufacturing started in 1987 as a front line supervisor in vehicle assembly. This included all aspects of safety, quality, productivity, cost and morale for operations. With experience as Assembly Plant Manager and eventually Assistant General Manager, his responsibilities increased to include both assembly plants including operations, maintenance, and engineering. He is a Certified Trainer in Global Problem Solving & Waste Reduction, Standardized Work and Kaizen Events.