PRODUCTION PLANNING AND CONTROL

DATE & LOCATION

22-24th November 2017, Monterrey

PRODUCTION PLANNING AND CONTROL

Toyota is the maximum standard when it comes to manufacturing efficiency and reduce waste reduction in processes. Over the past 20 years year, companies have directed a great deal of effort, time, and money to transform Lean Production. While Production efficiency is important, it is not the only thing. One of the keys to Toyota’s success is the role of Production Planning and Control in the organization. The section that manages the flow of customer information, suppliers, production, and engineering. As Atsushi Niimi (former President of TMMNA) once said: “PPC is where the true power of Toyota is”

Celestica offers flexible and innovative solutions to our customers through our Centers of Excellence. Leveraging our network of preferred suppliers, we help you bring your highly complex products to the market quickly, reliably and with a high level of quality.

The Monterrey operation of Celestica provides assembly of printed circuits, system assembly, box construction, value-added engineering, supply chain management, testing, direct compliance and repair, supported by solid laboratories of materials and test development equipment . The site serves customers in the communications and business market segments.

MAIN CLIENTS OF CELESTICA

OBJECTIVES

-

Show the Roles and Responsibility of PPC in a lean organization.

Show the Roles and Responsibility of PPC in a lean organization. - Trace the flow of information and material to create a Production Plan for 2 months to support the schedule of shipping to customers.

- Create a customer forecast of parts and components.

- Create a smoothed weekly production plan that will absorb order fluctuation.

- Measure the results of our trial.

AIMED AT

General Managers, Managers and Supervisors in Supply Chain, Production Planning or Lean Implementation that would like to understand how to maintain a consistent flow of information while supplying the plants with Just in Time product and materials.

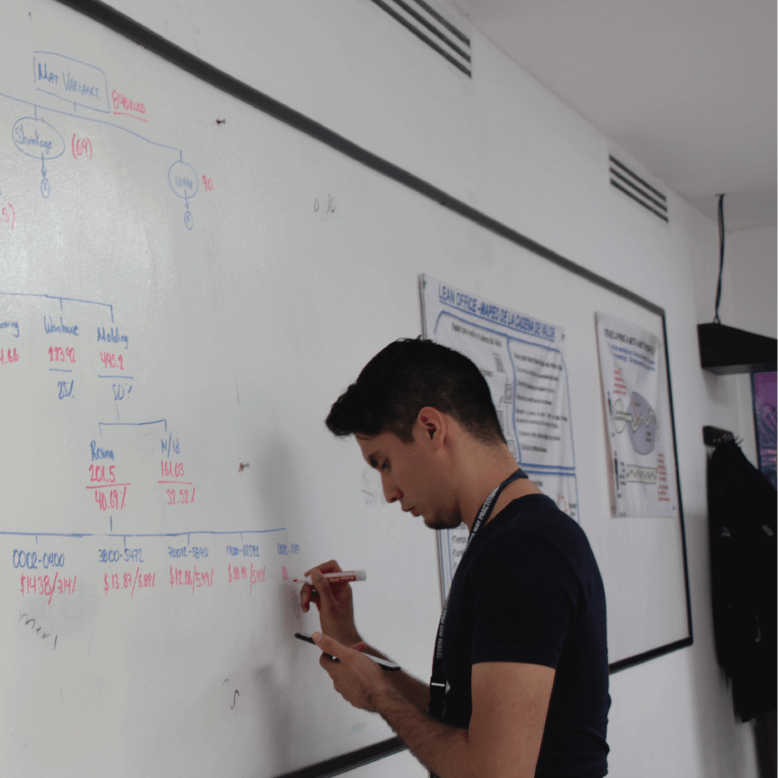

PROGRAM

Role of PPC in a Lean Company

Role of PPC in a Lean Company- Current Planning vs Production Planning and Control(PPC)

- Creating a Production Planning Group

- Creating a Production Plan (Theory)

- Defining TAKT time

- Creating a Production Forecast

- Creating the Production Plan

- Go, See and Understand (Gemba) at planning.

- Gemba Walk Production Line

- Map Current State production plan

- Value finished Goods

- Create Production Board (Maintenance Support)

- Create Finished Good Kanban (Staff Support)

Seleccionar objetivo de la línea de producción

Seleccionar objetivo de la línea de producción- Crear pronóstico de 2 meses de producción, 1 mes en firme.

- Crear plan semanal

- Establecer objetivos de inventario mínimo y máximo

- Inventario de producto terminado

- Crear un patrón de producción diario

- Establecer un tablero de Kanbans

- Equipo de Producción / Entrenamiento de distribución

- Revisión de Status

- Obstáculos y Contramedidas

- Desarrollo de listas de revisión

Asignar cada miembro a grupos pequeños de 2 o 3.

Asignar cada miembro a grupos pequeños de 2 o 3.- Confirmación del Proceso

- Lista de Problemas

- Reporte de Resultados

- Reporte de Lecciones aprendidas

- Crear tarea para la compañía anfitriona

INSTRUCTORS

JEFF MERRIS

Mechanical Engineering with Mayor on Business Management. Former Toyota TABC Manager. Former ToyotaAssistant Manager of Production Control. +25 years Toyota Experience at Toyota.

+25 YEARS TOYOTA EXPERIENCE Education · Mechanical Engineering with Mayor on Business Management. Jeff Merris have worked for Toyota Motor Manufacturing for 24 years and as an independent consultant for the past 2 years. During my career I have implemented TPS (lean production) in the Automotive (Toyota), snack food, beverage and the airline industries. Primary focus has been improvement in Production Planning, Internal Logistics (conveyance), External Logistics, Manufacturing and Finance. He has experience on create 1, 3, 5 year business plan, develop Strategies to integrate current business models with new business, develop and implement internal and external logistics strategies, develop and implement cross – dock (warehouse) strategies, develop and Implement Short and Long Term Production Plans to meet customer needs, develop production plan to meet TAKT time, teach & coach Toyota Problem Solving, develop and Implement Kanban Systems(material replenishment), develop manufacturing support equipment and develop internal delivery dollies. Merris has a Mayor on Mechanical Engineering by University of Kentucky (1983-1987), Major on Business Management by Northwood University (2005-2007). He was Production Control Assistant Manager from 2005 to 2007, Assistant Manager Production Control from 1997 to 2003, and Team Leader, Production Engineer (1988-2003) – at Toyota Motor Manufacturing Kentucky.

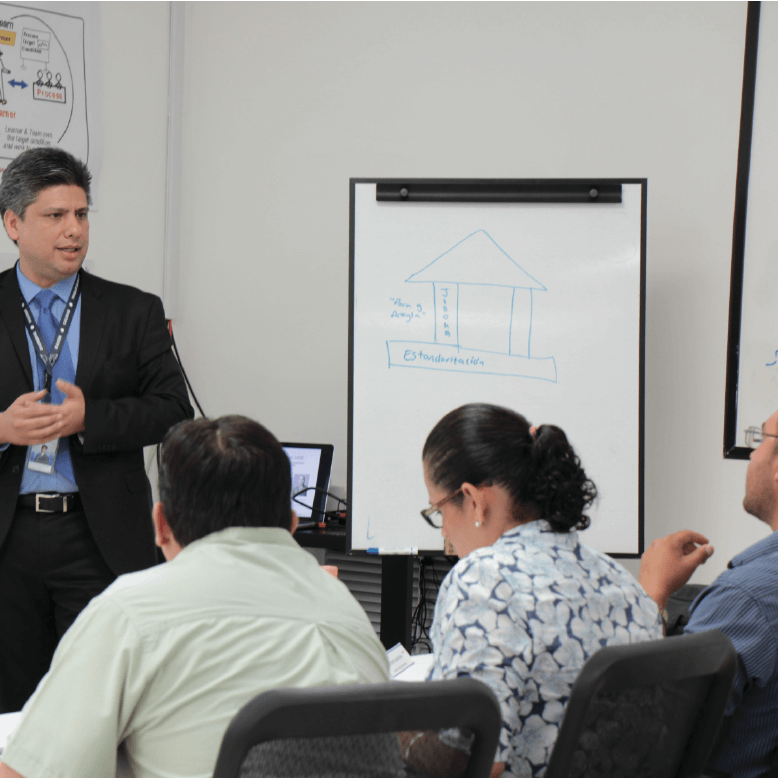

GUSTAVO VARELA

15 Years Teaching Experience. ALFRA Consulting Division Director. Former American Standard. Former Daltile Master Black Belt. 22 years experience. +17 years as Global Continuous Improvement Leader.

LEAN TRANSFORMATION THE TOYOTA WAY. · SIX SIGMA MASTER BLACK BELT. · 15 YEARS OF TEACHING EXPERIENCE. Education · Bachelor of Mechanics and Administration. · MBA from UANL. · Master Black Belt certified by ITESM. Based on his broad experience, Gustavo is expert applying a suitable approach for Continuous Improvement needed on the different organizations from a Business results optic, becoming an effective Coach for Top Management and support for The Toyota Way roles. Gustavo has learned The Toyota Way directly from its Author, Dr. Jeff Liker, and has applied it on Gemba as a Team with many Executives from Toyota specialized on General Management, TPM, Lean Mfg Tools, and Supply Chain. Gustavo has taught the Toyota Production System at all organizational levels and has applied over 50 companies of different sizes: Lean Leadership Systems (Hoshin Kanri, FMDS, and 8-Step Problem Solving), Toyota Kata for development, Supply Chain Management, TPM, Lean Manufacturing tools (5S’s, SW, SMED, Jidoka, Poka Yoke, Heijunka, JIT, etc.), and Lean Office approach. On Six Sigma, Gustavo as Master Black Belt has trained and certified +500 Black Belts, Green Belts, and Yellow Belts. Gustavo has +20 years of experience on Continuous Improvement, Manufacturing, Process Engineering and Quality in large companies: Motor Wheel (Automotive), Kodak, Philips, Daltile, American Standard. He has +12 years of experience as Vice/President Staff as Continuous Improvement Director for American Standard México and Master Black Belt Champion for Daltile México. He has deployed programs that have achieved +$110 Million USD in savings with +3,000 projects on all departments: R&D, Engineering, Manufacturing, Maintenance, Quality, Logistics, Supply Chain, Sales, Marketing, Finance, HR, Energy. Over his 22 years experience, Gustavo has been exposed to many different organizations applying suitable Lean approaches on a variety of systems with diversity on leadership styles. Master Degree Professor at Tec Milenio and Professor at ICAMI Business School. Lean Manufacturing and Six Sigma lecture in México on various Universities and Forums.

SERVICES INCLUDED

The Training Certificate will be finalized 6 months after attending the course and presenting the implementation and results obtained.

- Coffee Break & Lunch

- Manual

- Certificate of training

- Simultaneous Translation Service ($130.00 MN + Tax / per day)